Highest Component Quality in Aluminum Machining

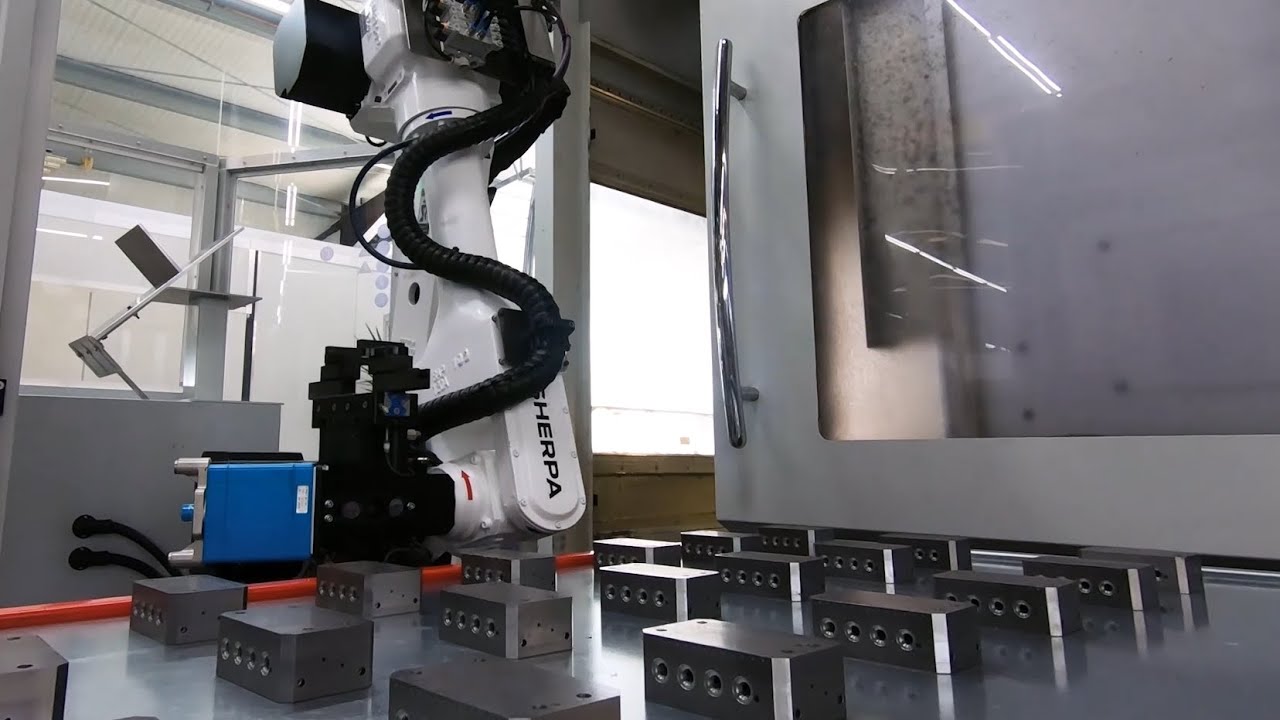

When implementing automation solutions in the manufacturing process, specific requirements must be considered to increase productivity. The integration of the SherpaLoader® into this process illustrates how coordinated technologies can meet these requirements and optimize the production workflow. This video shows the manufacturing process of aluminum profile rails in a Spinner 4-axis machining machine enhanced by a SherpaLoader® M50 with a vacuum suction device adapted to the application. The gentle and precise handling of the aluminum profile rails by the robot arm brings a significant increase in the efficiency of the manufacturing process with the Spinner 4-axis machining machine.

Safe and Efficient: Automated Machining for Spinner CNC Machining Machines

The loading robot grips the aluminum profile rails with the vacuum suction device. This technology enables the profile rails to be gripped safely while simultaneously placing the component on a pre-positioning tray without damage. On the pre-positioning tray, the component is pressed against a stop to ensure exact alignment in the X and Y axes. Through precise alignment on the pre-positioning plate, a continuous manufacturing process and highest component quality are ensured. Before inserting the raw part into the Spinner CNC machining machine, the SherpaLoader® M50 cleans the clamping device with a compressed air nozzle to remove residues such as coolants, lubricants, and chips. Potential sources of error are thus minimized and highest process reliability is guaranteed. The automatic cleaning of the clamping devices and the machining area also leads to an extension of tool life and thus to a reduction in maintenance effort. Subsequently, the robot arm positions the component in the clamping device, which closes automatically, as do the motor-driven doors of the Spinner CNC machining machine.

One aspect of the process is the preparation of the next workpiece by the loading robot while the machine is still machining the current component. The synchronization of work steps results in a reduction of auxiliary times and a maximization of spindle time of the Spinner CNC machining machine.

Maximum Efficiency Through Automated Cleaning and Storage

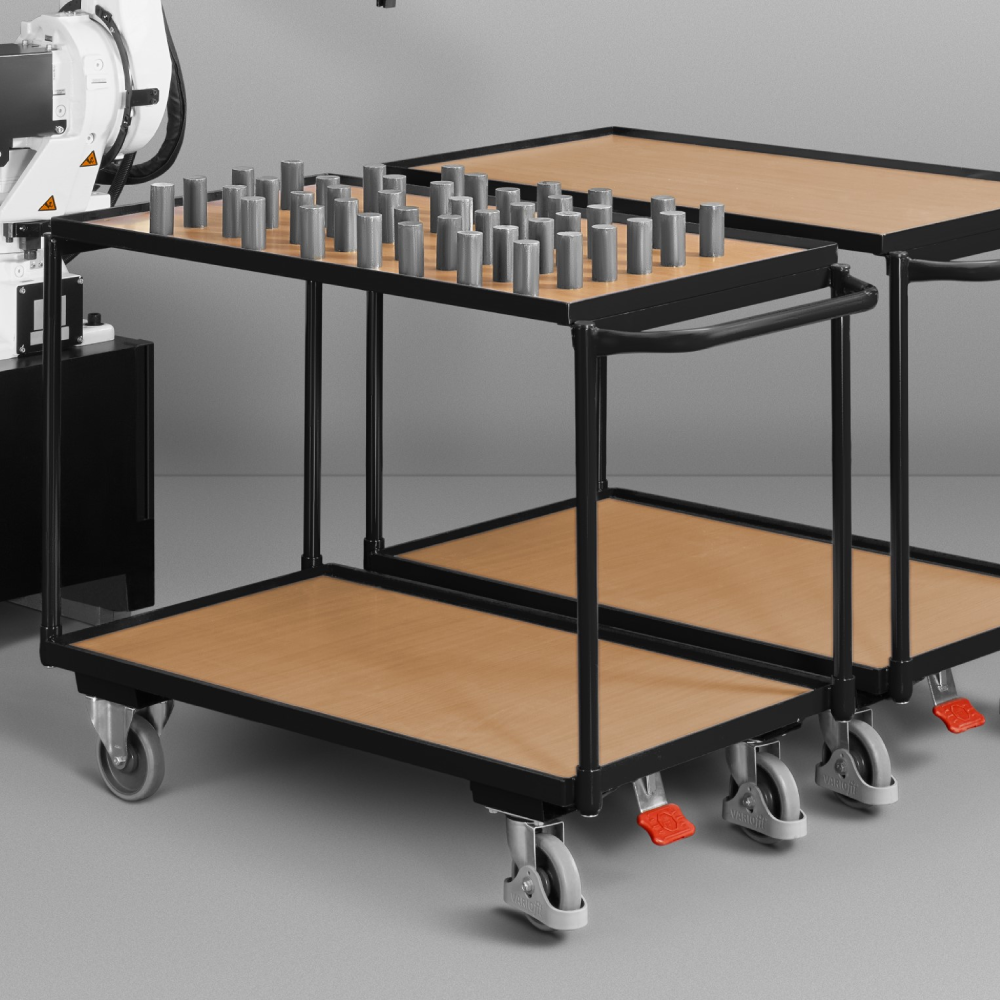

After completion of machining, the finished component is cleaned with a blow nozzle and removed by the robot arm to place it on the positioning chute and grip the new raw part for the next machining step. The cleaning of the aluminum profile rails removes coolant and lubricant residues as well as chips from the components and ensures that the robot arm can transport the components gently and safely with the vacuum suction device after machining. After the new raw part has been inserted into the clamping device of the Spinner CNC machining machine, the finished machined component is transferred by the robot to the SpaceBox, a specially designed material storage with ten drawers, each capable of accommodating up to seven of the shown components. The high component capacity of the SpaceBox and the ability of the loading robot to individually occupy the storage places result in a reduction of manual interventions and thus in increased machine runtime and increased efficiency of the manufacturing process. The automated machining of aluminum profile rails requires not only precise handling technology but also a comprehensive safety concept. The system is equipped with multiple monitored protective devices. A separating protective device protects against intervention, crawling under, and reaching over. A safely monitored inspection door at the rear enables protected access for maintenance purposes. Additionally, robot position and speed are continuously monitored to ensure safe operation.

Maximum Efficiency and Quality: Machining Automation of the Spinner 4-Axis Machining Machine

The SherpaLoader® M50 optimizes manufacturing processes of a Spinner CNC machining machine through reliable and automated material handling. The combination of gentle workpiece handling and automated cleaning reduces manual interventions and increases process reliability. Through the reduction of auxiliary times and optimized machine runtime, the SherpaLoader® M50 contributes to stable, economical, and future-proof manufacturing while considering the highest safety standards.