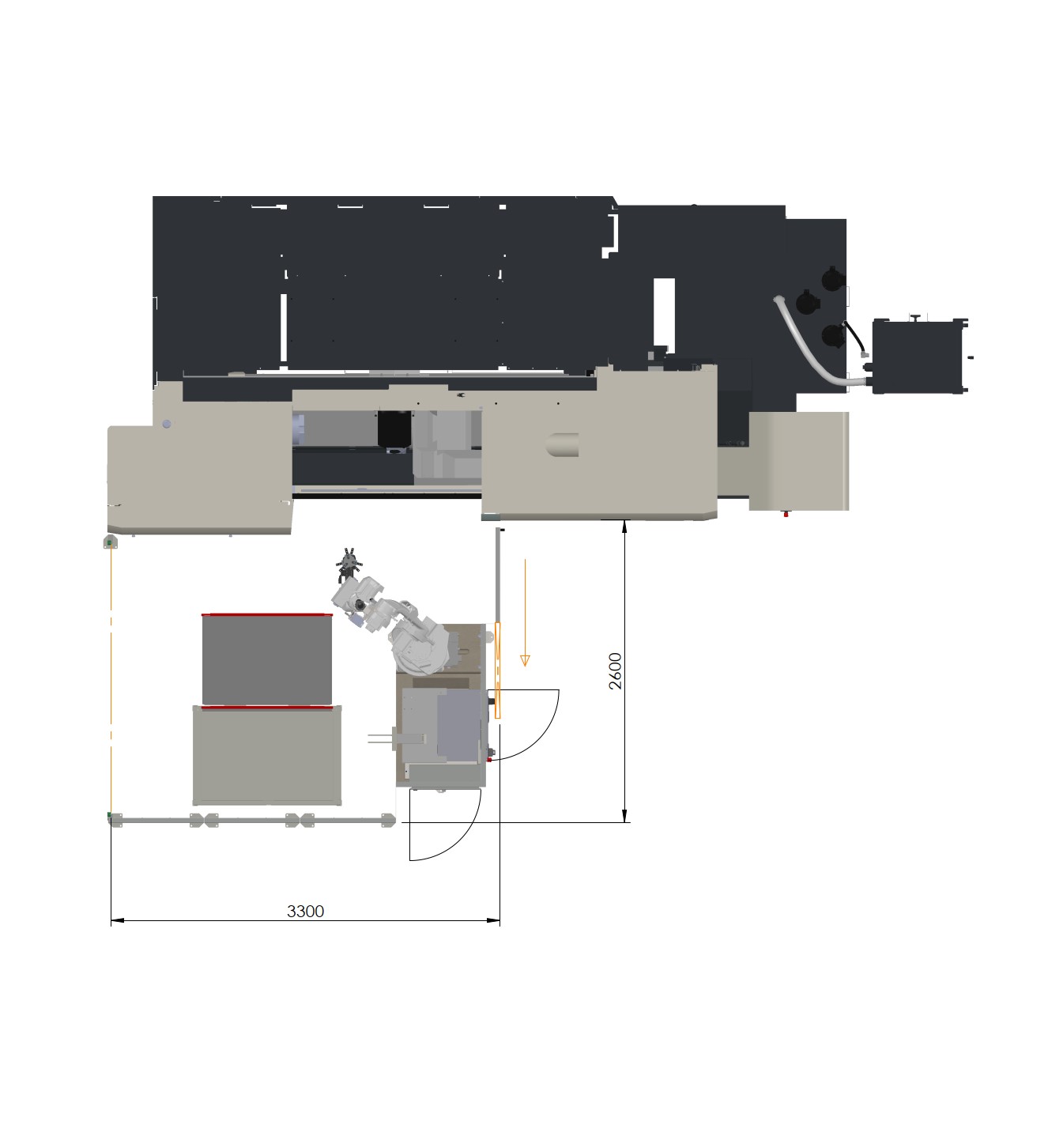

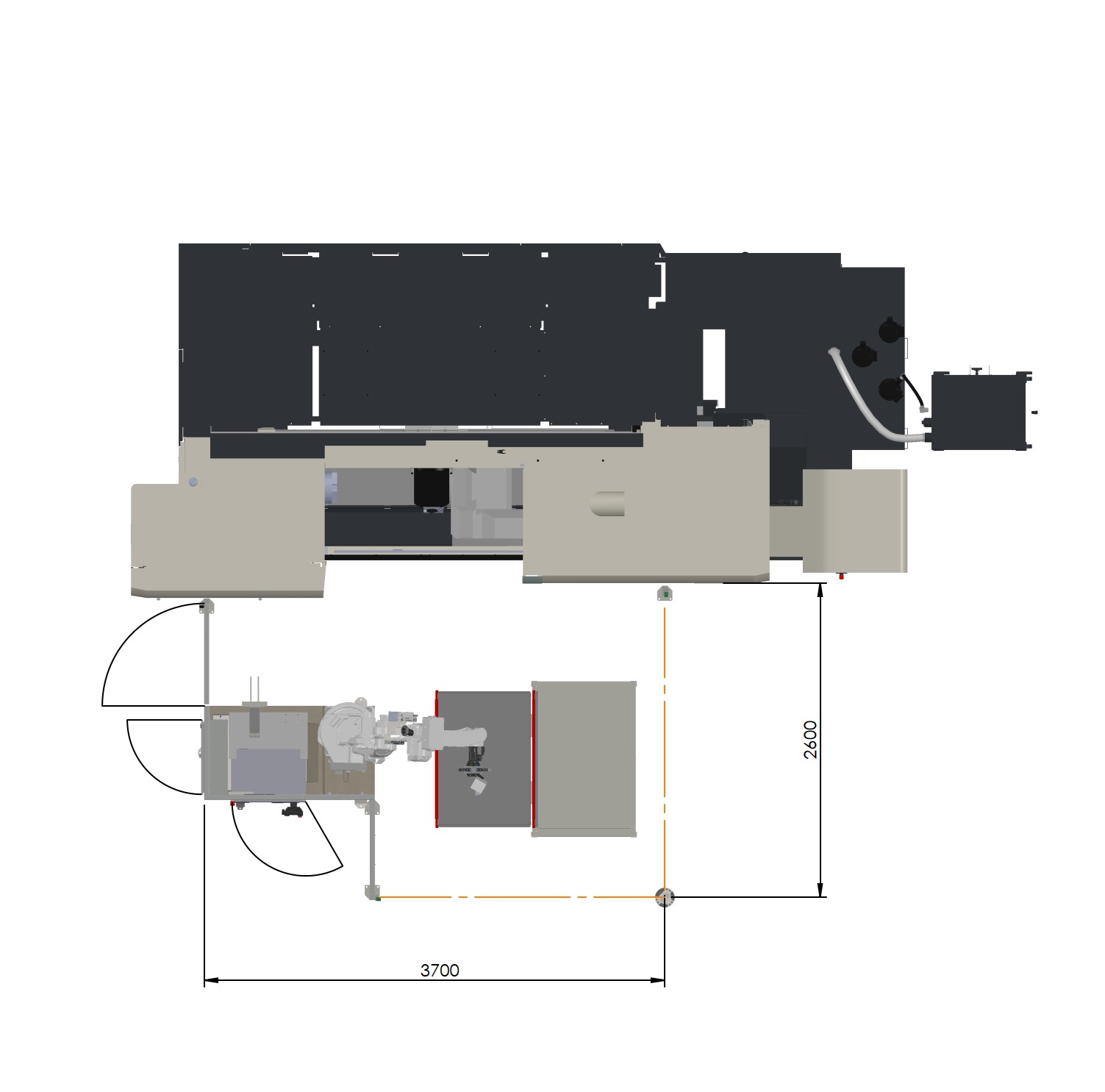

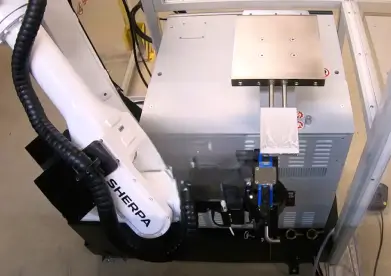

How does the SherpaLoader® work?

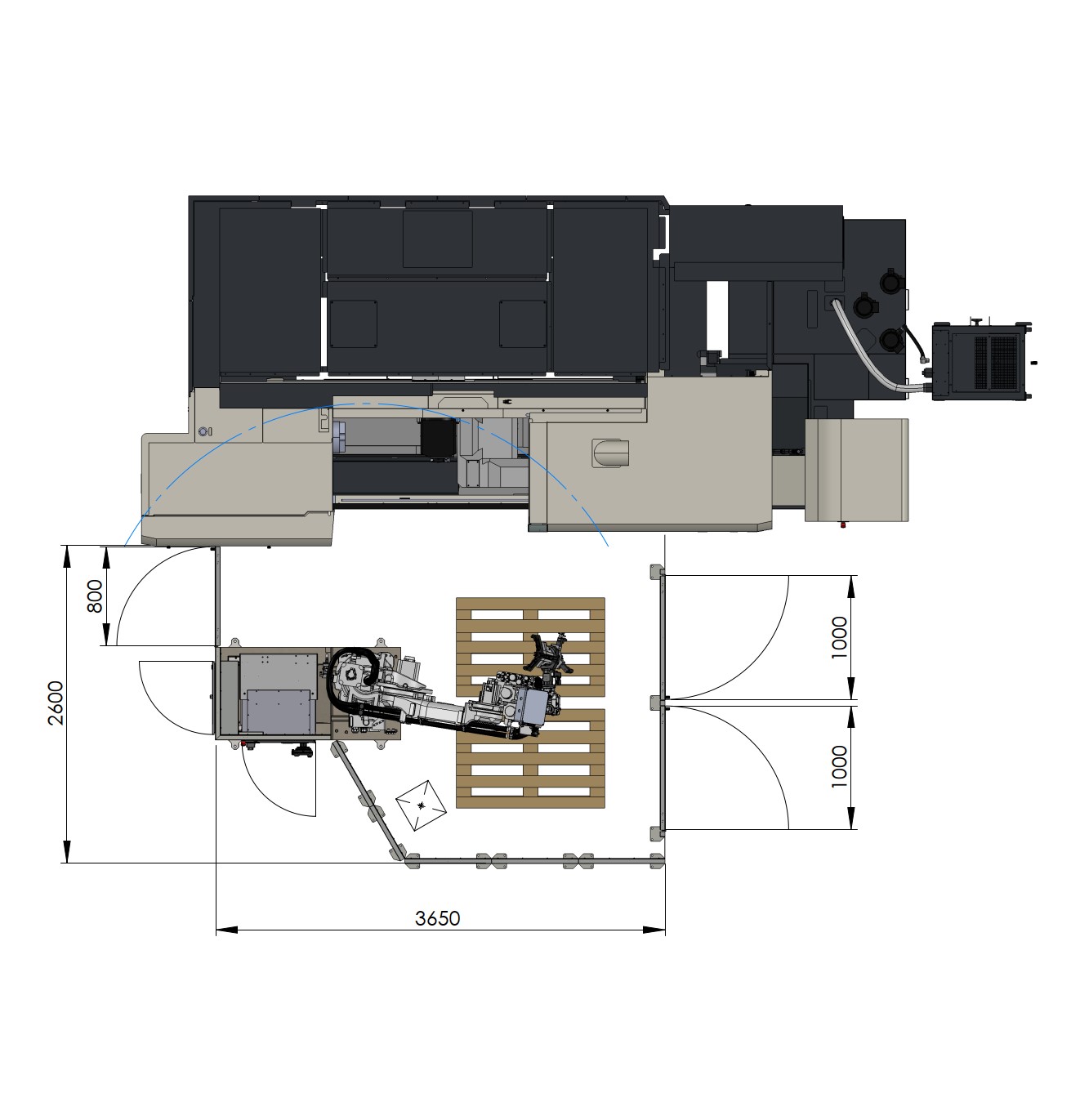

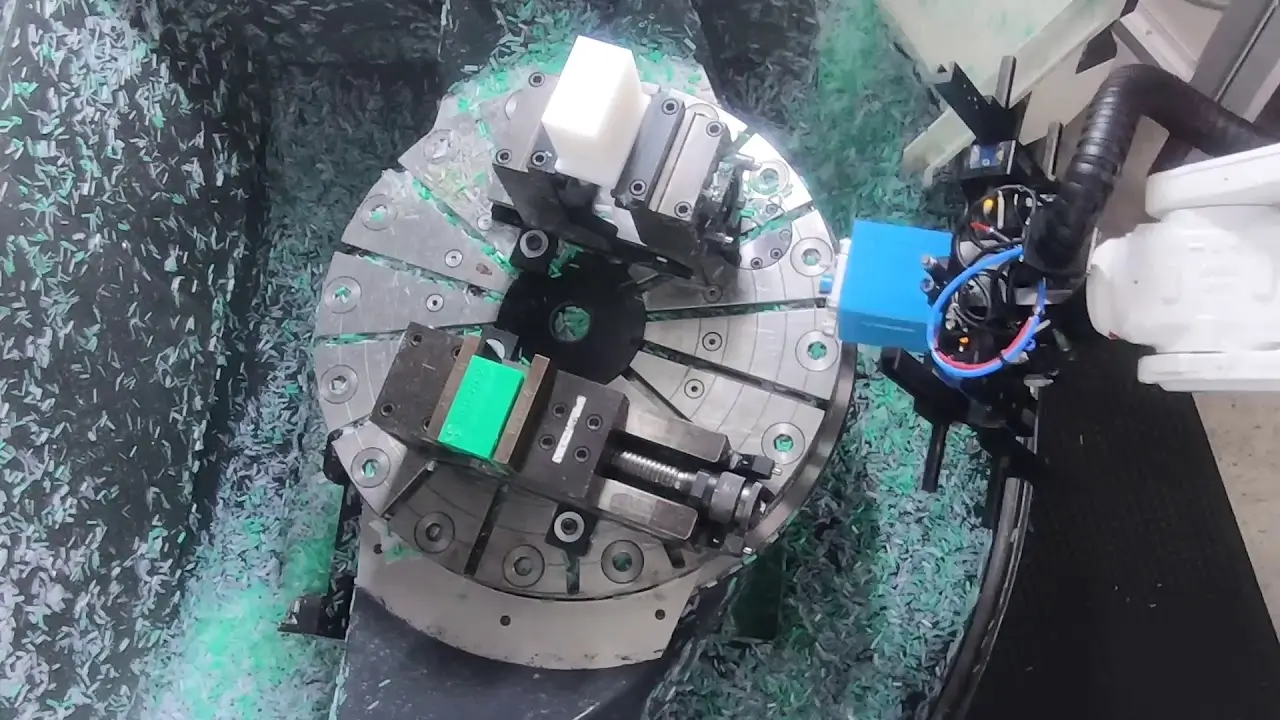

Machine operators with no prior robotics knowledge can easily

use the SherpaLoader®. Setup is completed in three simple steps:

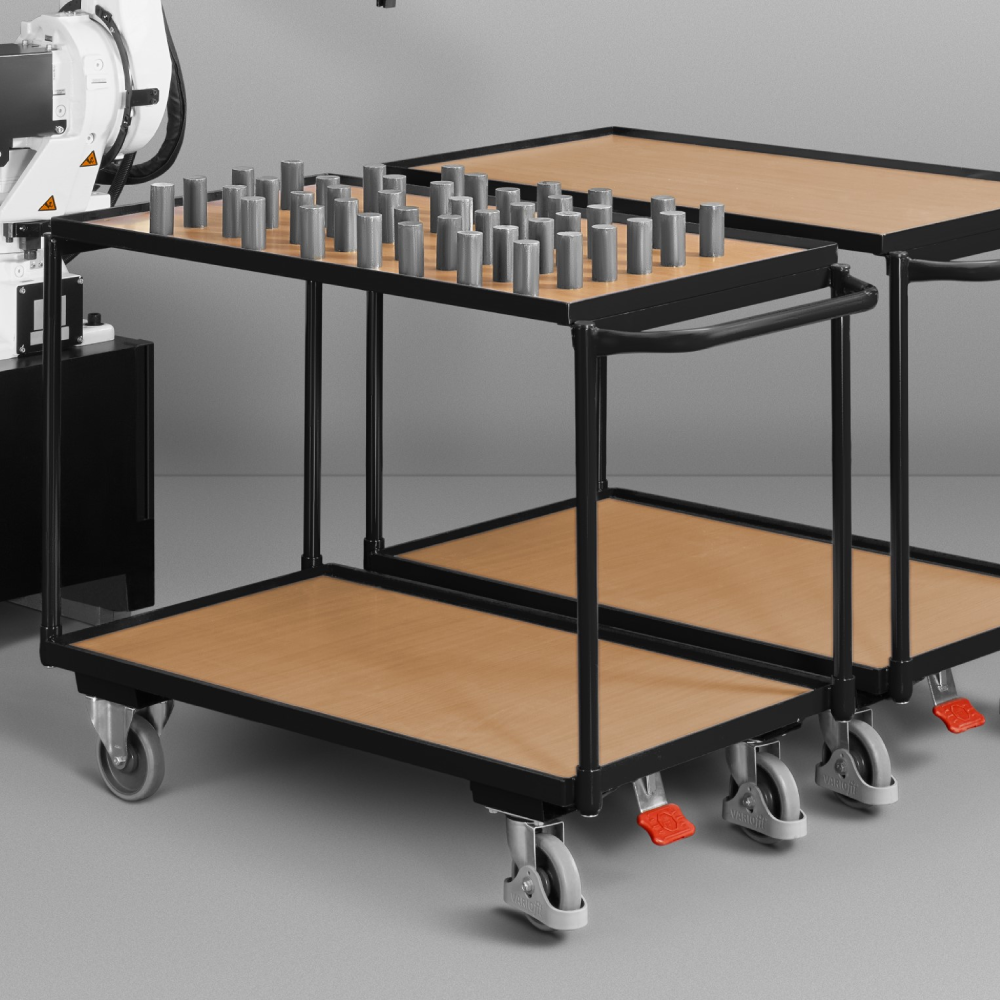

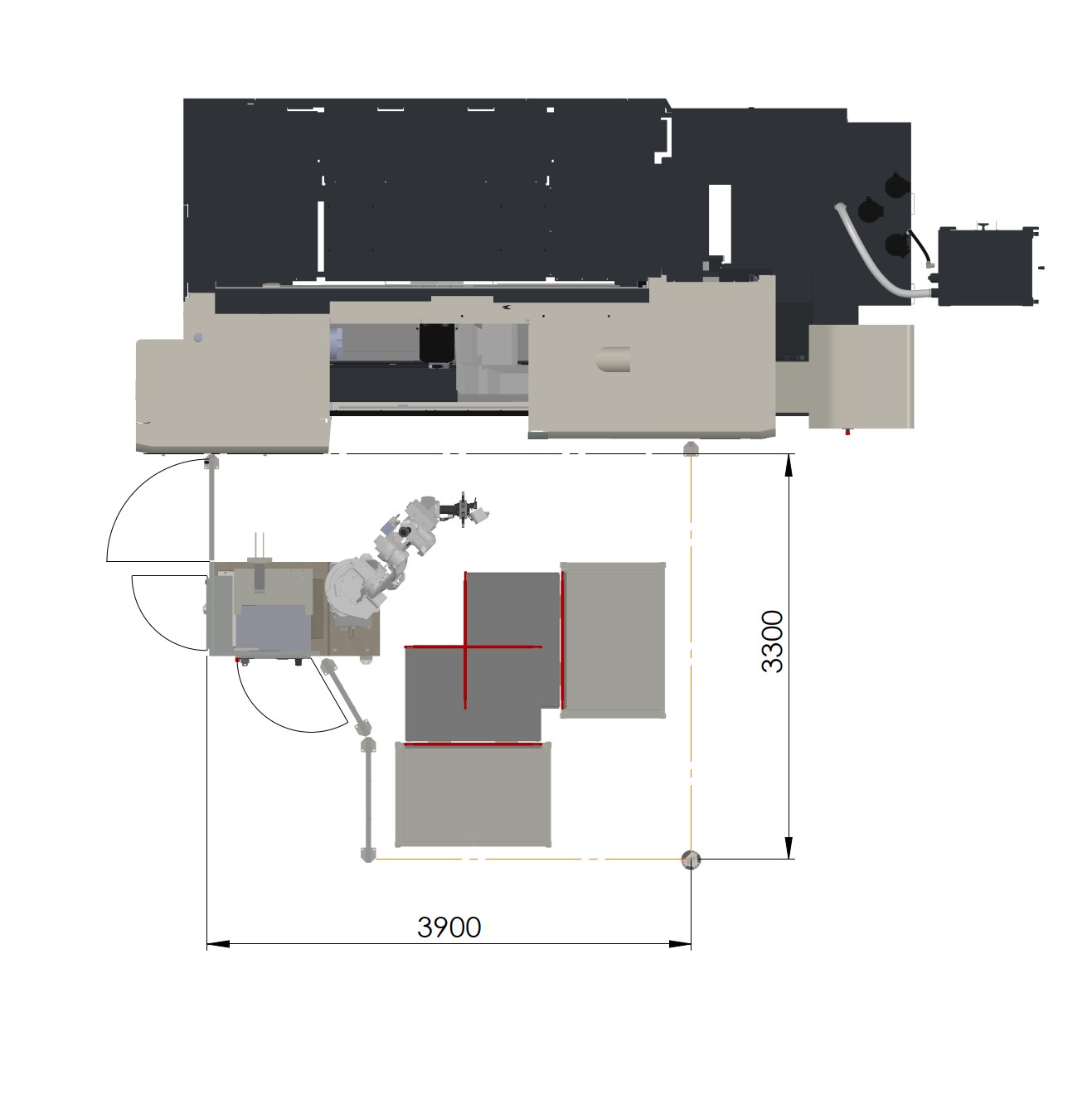

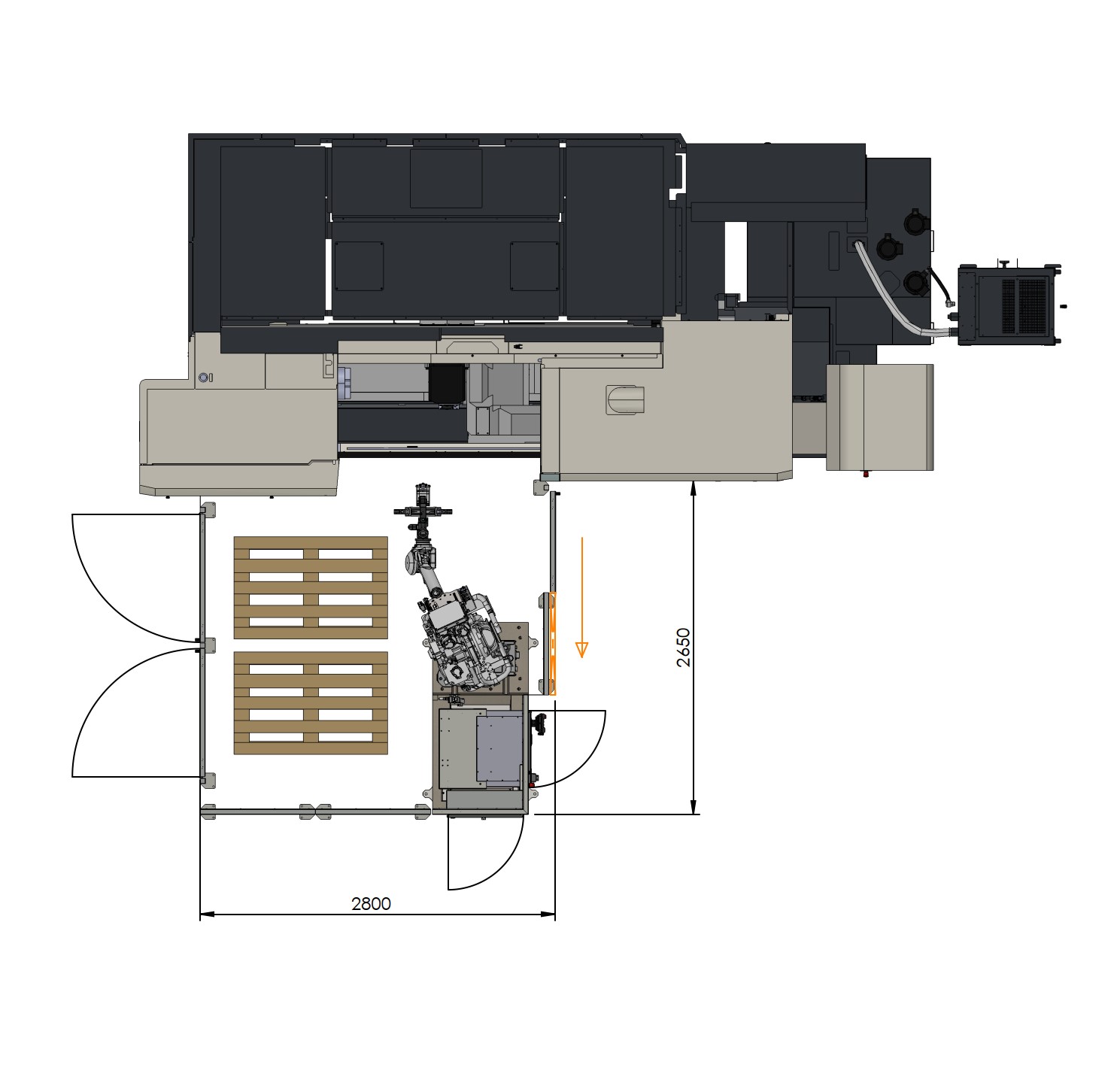

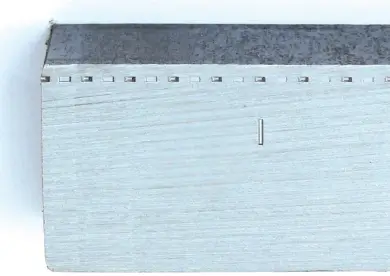

1. Supply blanks

Arrange raw material on the material staging decice, in no particular arrangement Learn more

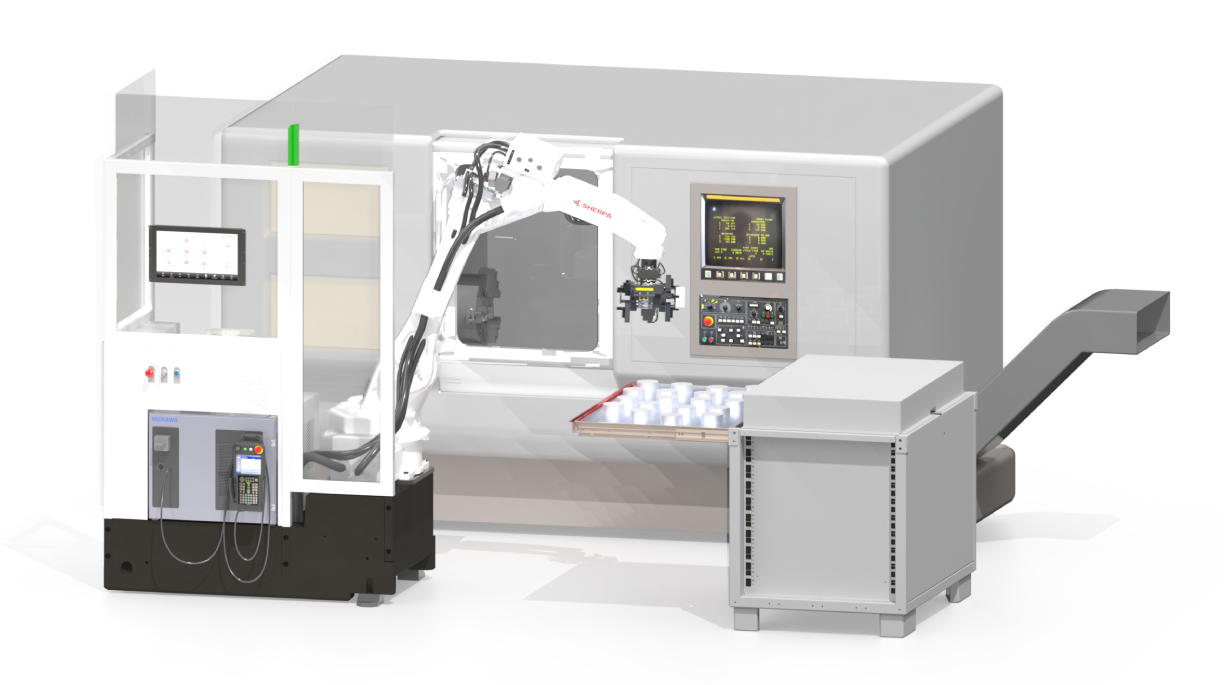

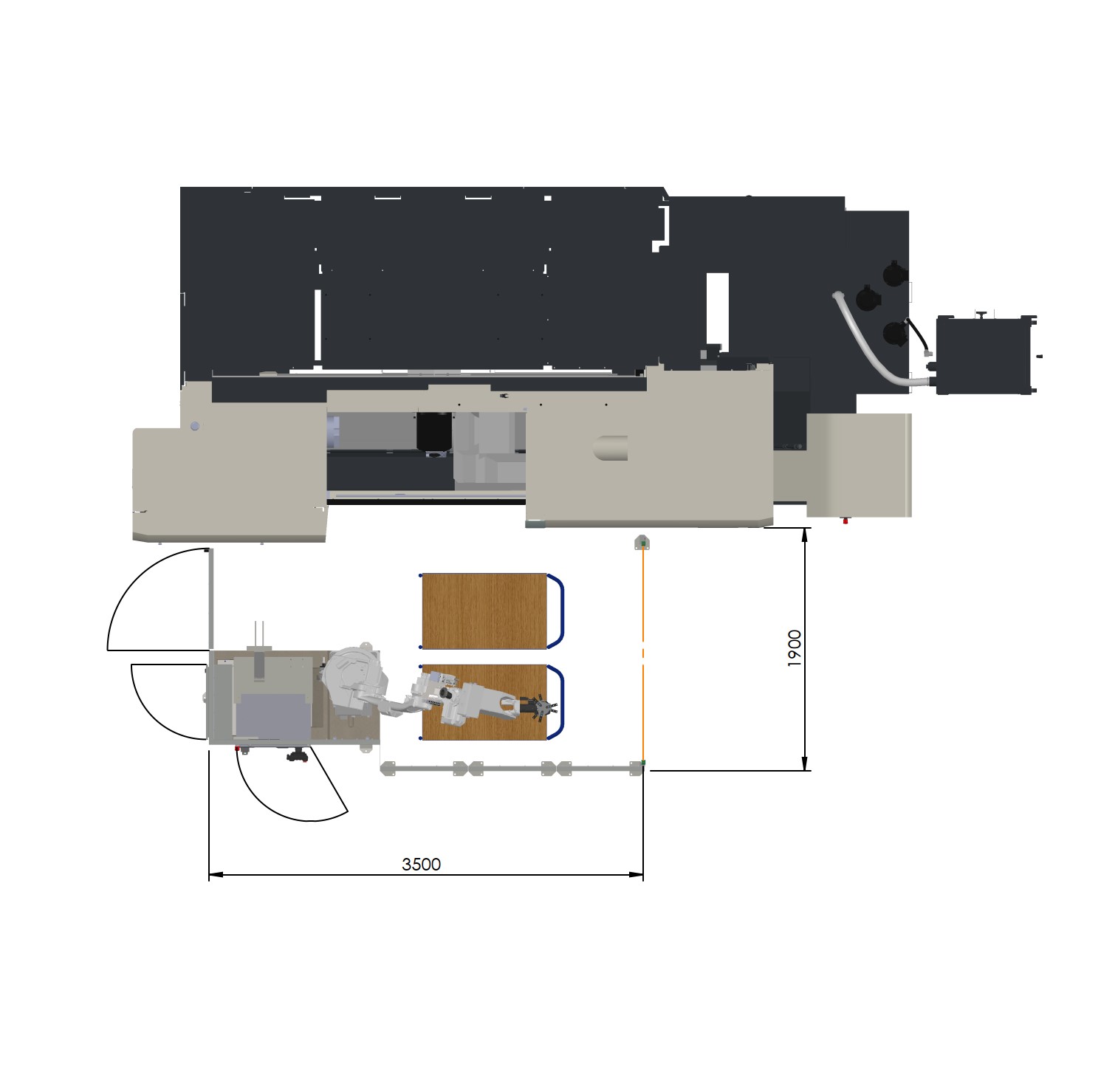

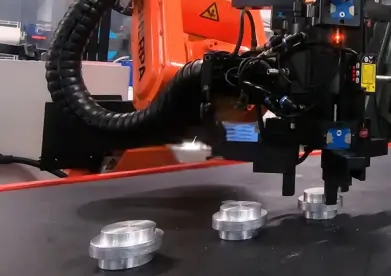

2. Adjust robot grippers

Set width of the robot grippers to match the workpiece dimentions Learn more

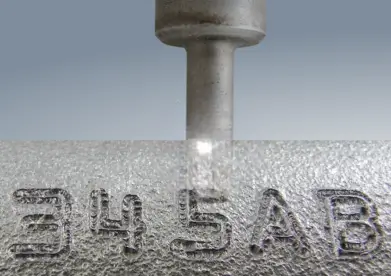

3. Select job

Choose a saved job or create a new one in the dialog control – then press Start! Learn more