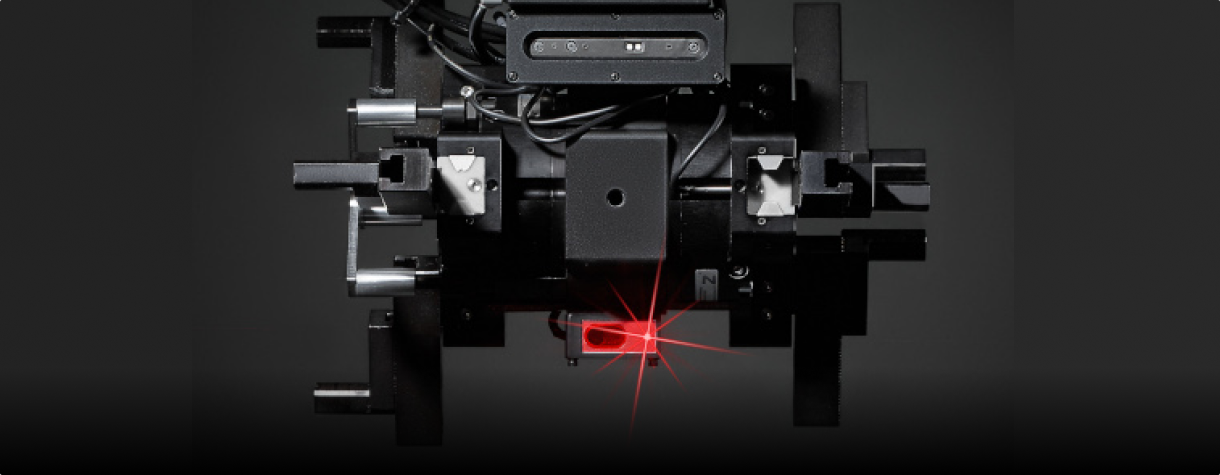

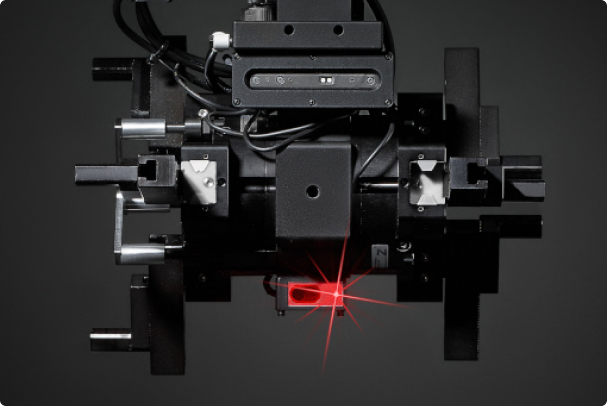

SherpaVision®

Symbiosis of 3D-

camera and laser

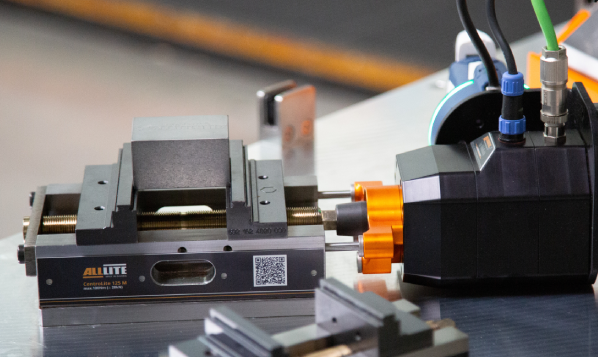

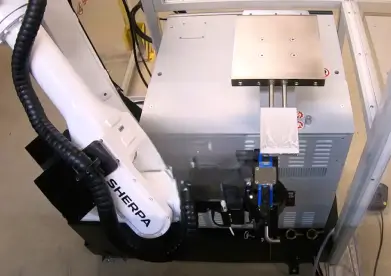

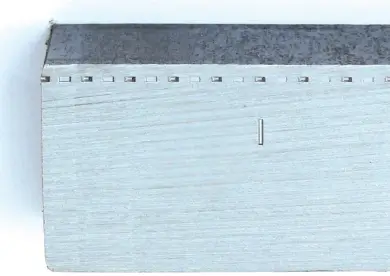

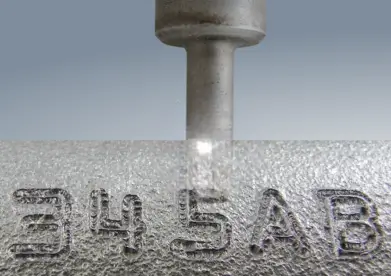

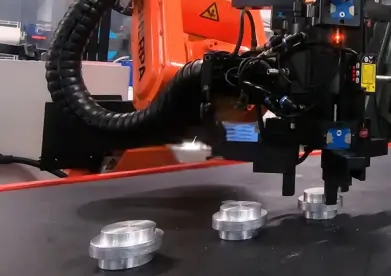

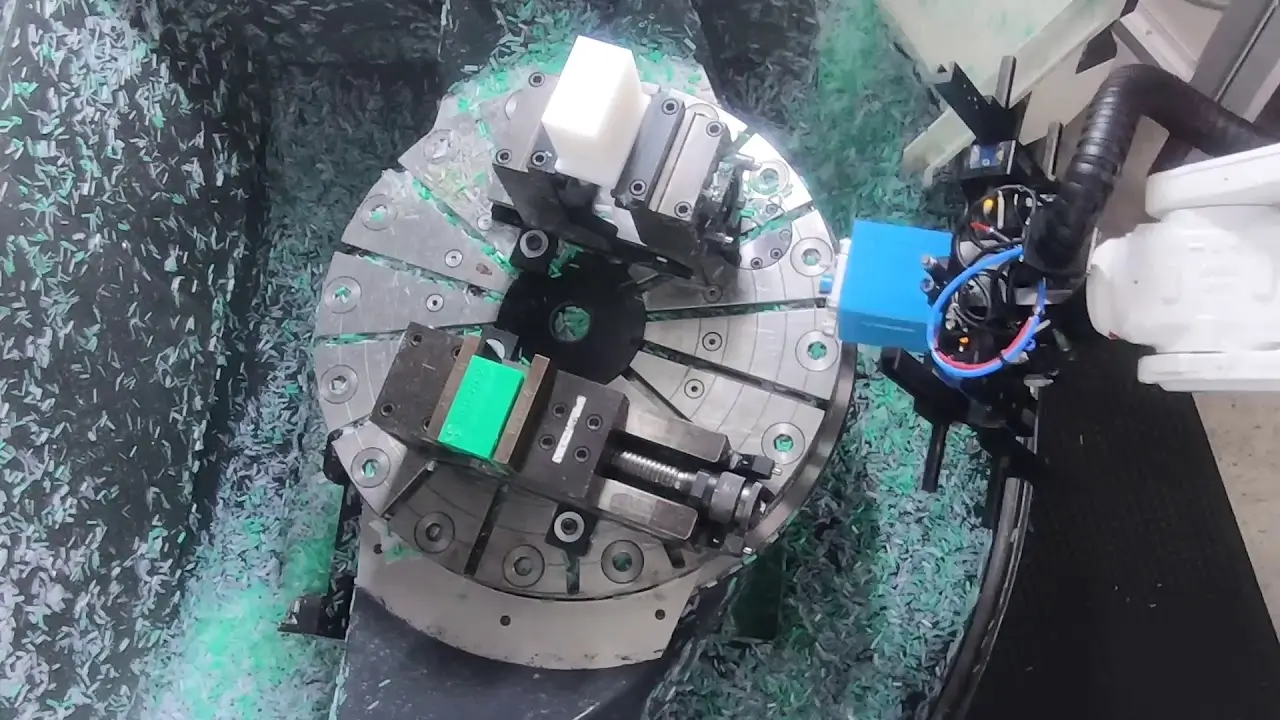

The heart of the system is the 3D camera laser system. It detects workpieces where you have placed them, without grid plates, stops or matrices. This saves you from constantly having to retool mechanical devices, laborious programming of change magazines and expensive and vulnerable rotary and stacking tables. A cover flap covers the optical sensors when used in harsh operating conditions.