Efficient Machining of Plastic Gears Through Robot Integration

The automated machining of plastic components offers great potential for economical and process-reliable production. This video demonstrates the automation of the machining process of workpieces made from polypropylene (PP) on a Haas ST-25Y through the integration of a SherpaLoader® T88. The combination of modern CNC machining machine and robust robot automation reduces manual interventions, increases productivity, and simultaneously ensures consistently high component quality.

Automated Raw Part Handling with Precise Alignment

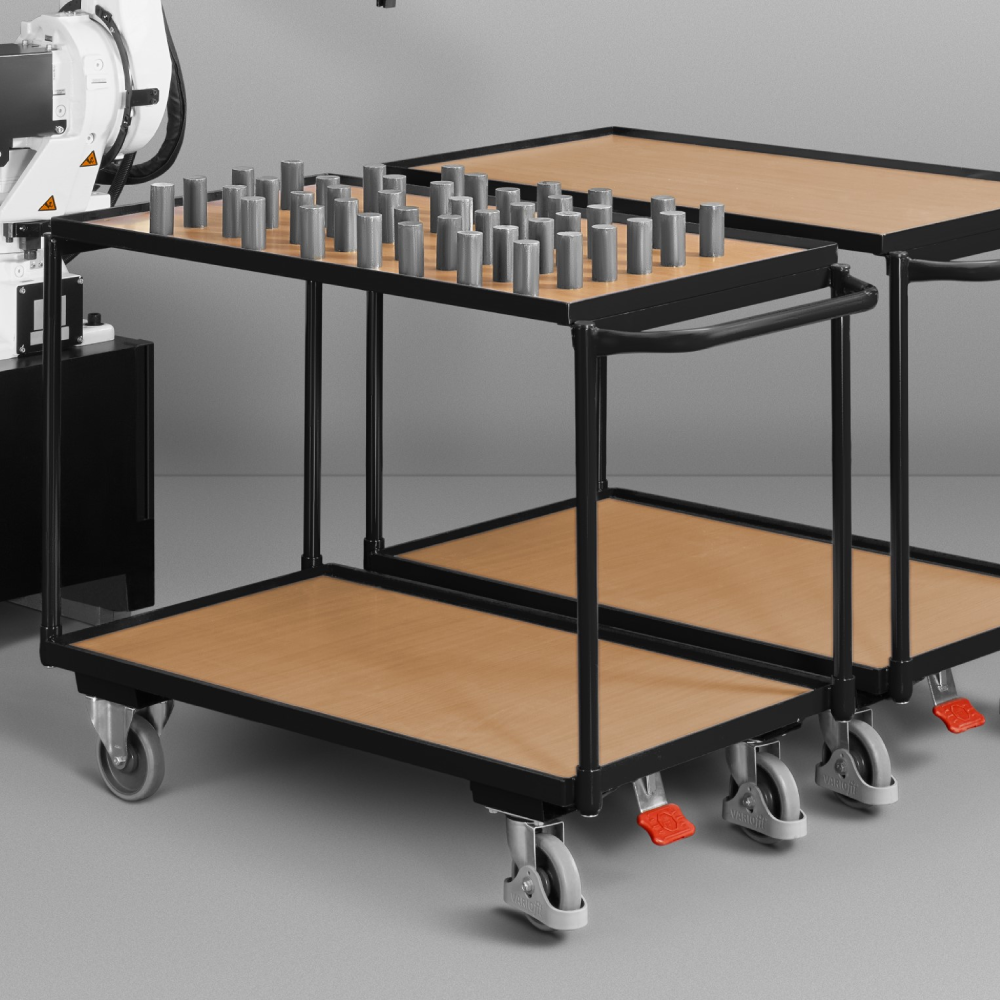

The SherpaLoader® T88 is equipped with two three-jaw grippers including pressure star, which enable safe and stable handling of the plastic blanks. The material storage in this case consists of two pallets – a raw part and a finished part pallet – which are arranged at defined positions within the system. This exact positioning enables the SherpaLoader® T88 to precisely remove the stacked raw parts with the raw part gripper and position them on the alignment plate. This measure ensures process-reliable and repeatable clamping in the chuck of the Haas ST-25Y – a decisive factor for the dimensional accuracy and quality of the plastic components.

Automated Chuck Cleaning for Consistent Component Quality

Before clamping the plastic blank in the chuck of the Haas ST-25Y, automated cleaning with compressed air is performed. The cleaning of the chuck from manufacturing residues increases the repeatability of clamping and thus process reliability. Additionally, damage to the plastic components is prevented and maintenance efforts are reduced. After the SherpaLoader® T88 has left the workspace of the Haas ST-25Y, the door closes automatically and the machining process begins. While the first raw part is being machined, the SherpaLoader® T88 already removes the next raw part from the raw part pallet and positions it on the alignment plate. Through the implementation of synchronized processes, auxiliary times are minimized and maximum spindle runtime is achieved. After completion of machining, the door of the Haas ST-25Y opens automatically. The SherpaLoader® T88 removes the finished part from the chuck, cleans the chuck again, and clamps the next raw part. The finished part is placed by default on the finished part pallet of the material storage. Optionally, the finished part can also be placed in an ejection station if manual inspection is required. The finished part can be removed from the ejection station during operation. This enables manual quality control during operation and no production stops for sampling are necessary. This achieves maximum machine utilization of the Haas ST-25Y.

Increased Process Reliability and Efficiency Through Machining Automation of a HAAS ST-25Y

The combination of the CNC machining system Haas ST-25Y and the SherpaLoader® T88 demonstrates how complete automation can be implemented economically and reliably even in the machining of plastic components. Through synchronized processes, automated cleaning, and flexible handling of finished parts, consistently high component quality is achieved with maximum machine utilization. The automation of the process reduces manual interventions and thereby increases process reliability. Simultaneously, operating personnel are relieved and can be deployed for higher-value tasks. This optimizes resource utilization within manufacturing. Furthermore, the elimination of manual work steps ensures constant reproducibility and minimizes potential sources of error. The automation of the machining process of the HAAS ST-25V is carried out in compliance with the highest safety standards. The entire robot cell is surrounded by a protective enclosure. This protective device provides protection against hazards from intervention, crawling under, and reaching over. Additionally, robot position and speed are safely monitored. The operating status of the system is indicated via a signal lamp.