Efficiency Enhancement Through Automation in Machining Technology

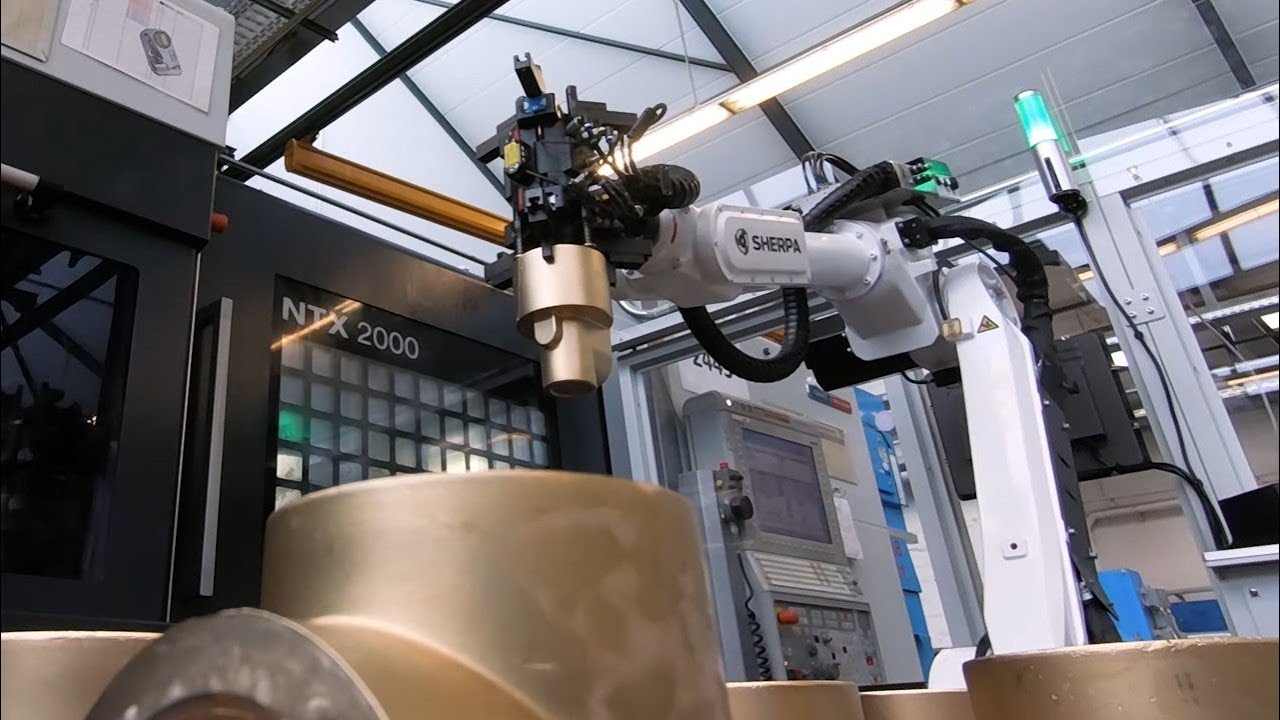

Automation in machining technology enables efficient processing of workpieces. Through the integration of the SherpaLoader into a CNC lathe, the productivity of the system can be maximized. This video shows a Mori Seiki NL2000 lathe with main and counter spindle enhanced by automated material handling to process cast blanks precisely and efficiently.

The Machining Process: From Blank to Finished Part

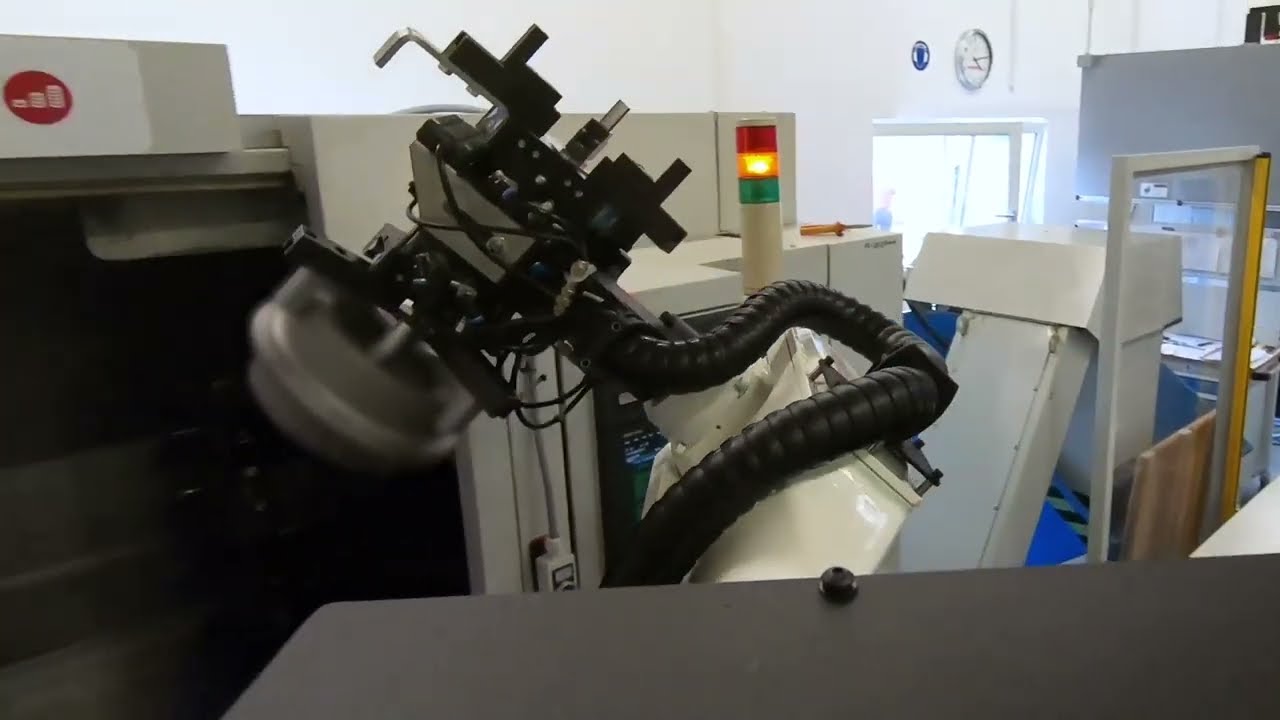

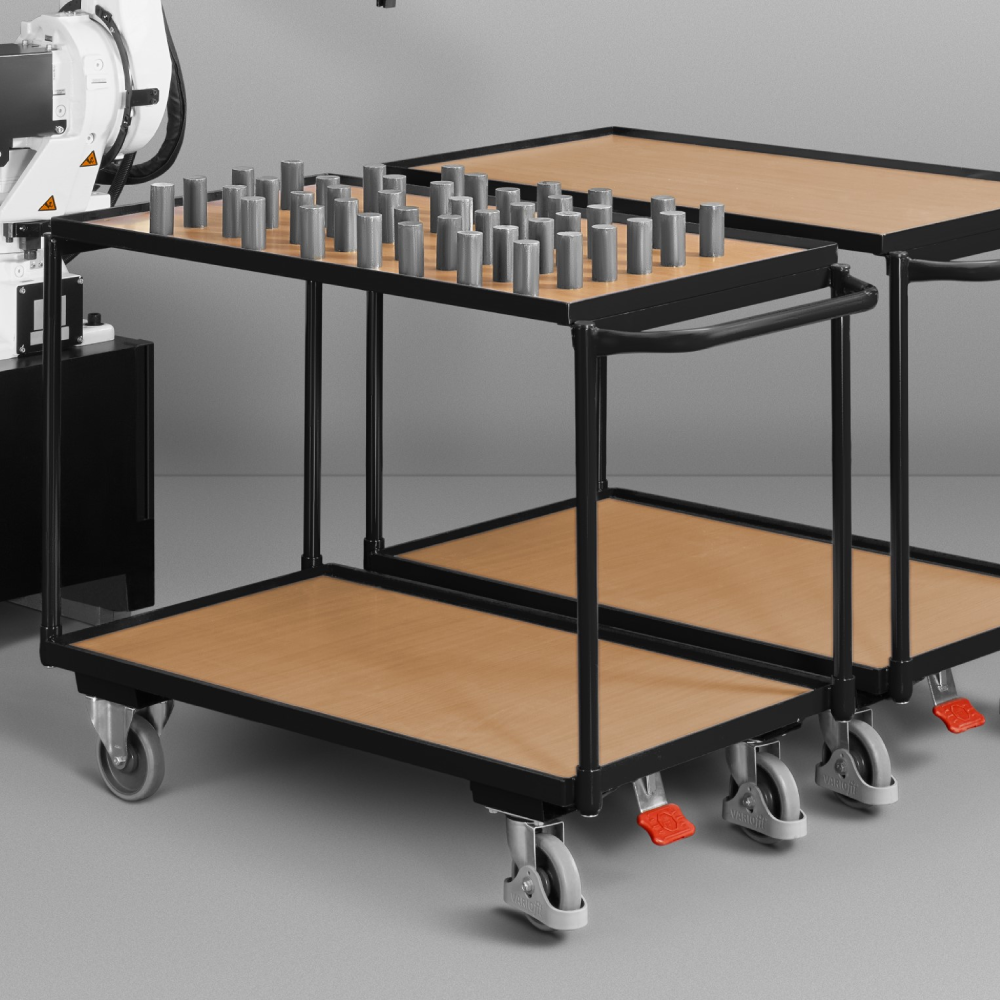

The automation process begins with the pickup of the cast blank from the material provisioning by the SherpaLoader using a raw part gripper. The capture of components is enabled by the SherpaLoader’s advanced camera-based detection technology. Subsequently, the component is placed on a pre-positioning plate. When picking up from the positioning plate, the pressure star of the robot gripper is pre-tensioned. This ensures that the workpiece is correctly aligned before it is inserted into the main spindle of the lathe. The axial pressing force of the pressure star during clamping ensures flat contact of the component with the clamping device.

Parallel Workflows for Maximum Productivity

During machining in the CNC lathe, an automatic transfer from the main spindle to the counter spindle of the machining machine takes place. After completion of the machining process, the component is removed from the counter spindle of the machine. The robot inserts the next raw part into the main spindle in the same work cycle. Through the linking of the two process steps of unloading and loading, the automation of the machining process with the integration of the SherpaLoader enables a reduction of auxiliary times and a maximization of machine runtime.

Automated Cleaning of Finished Parts

After machining, the workpiece is automatically cleaned. For this purpose, the robot holds the component in a cleaning blow box, where it is moved and simultaneously freed from chips and cutting fluid residues with compressed air. Finally, the cleaned finished part is placed back on the material provisioning plate before the robot picks up the next cast blank for machining.

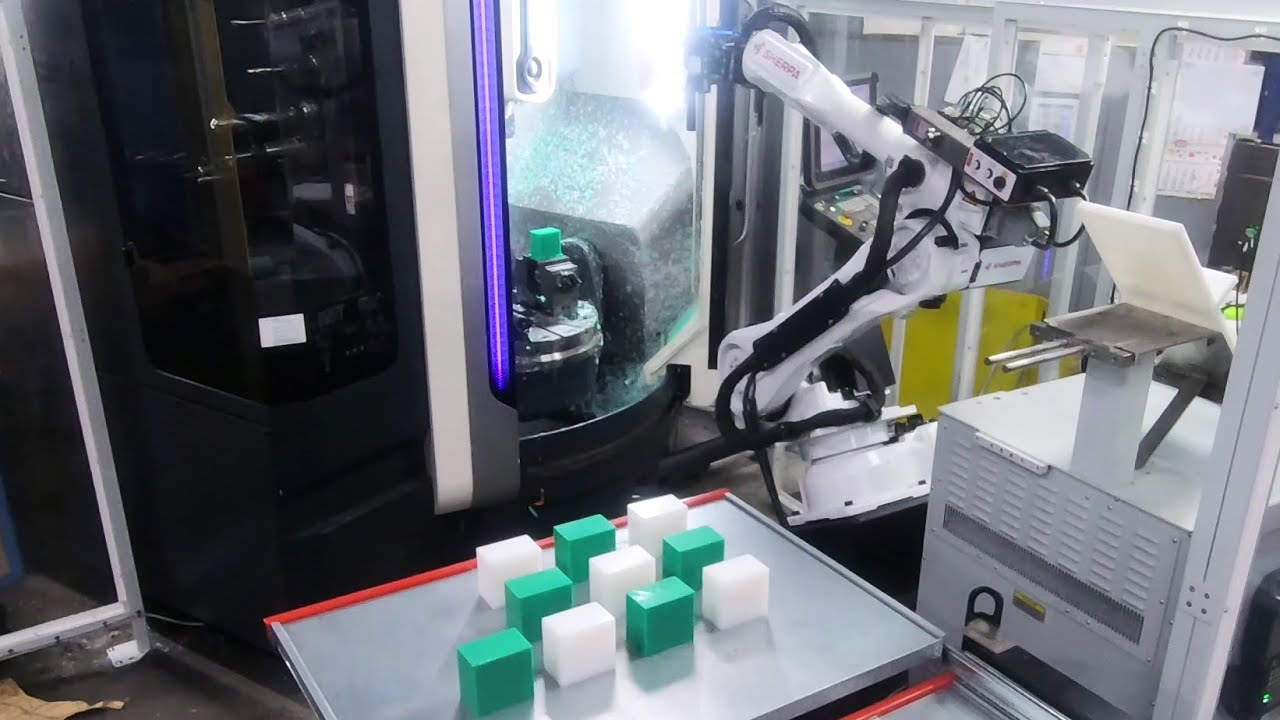

Flexible Changeover for Different Component Geometries

The SherpaLoader enables uncomplicated changeover of component geometries to be machined. Through the integration of advanced camera-based detection technologies, the automation process can be manually adapted to different workpiece shapes. This increases flexibility in the production process and enables response to rapidly changing manufacturing conditions.

SherpaLoader® and Mori Seiki NL2000: The Perfect Combination for CNC Automation

In summary, the SherpaLoader® offers a comprehensive solution for automation in the use of CNC machines. By considering various customer requirements and technical challenges, the SherpaLoader® helps companies achieve their production goals efficiently and safely, while always complying with the highest safety standards.