Continuous Material Flow for High Spindle Utilization of the Hermle C400

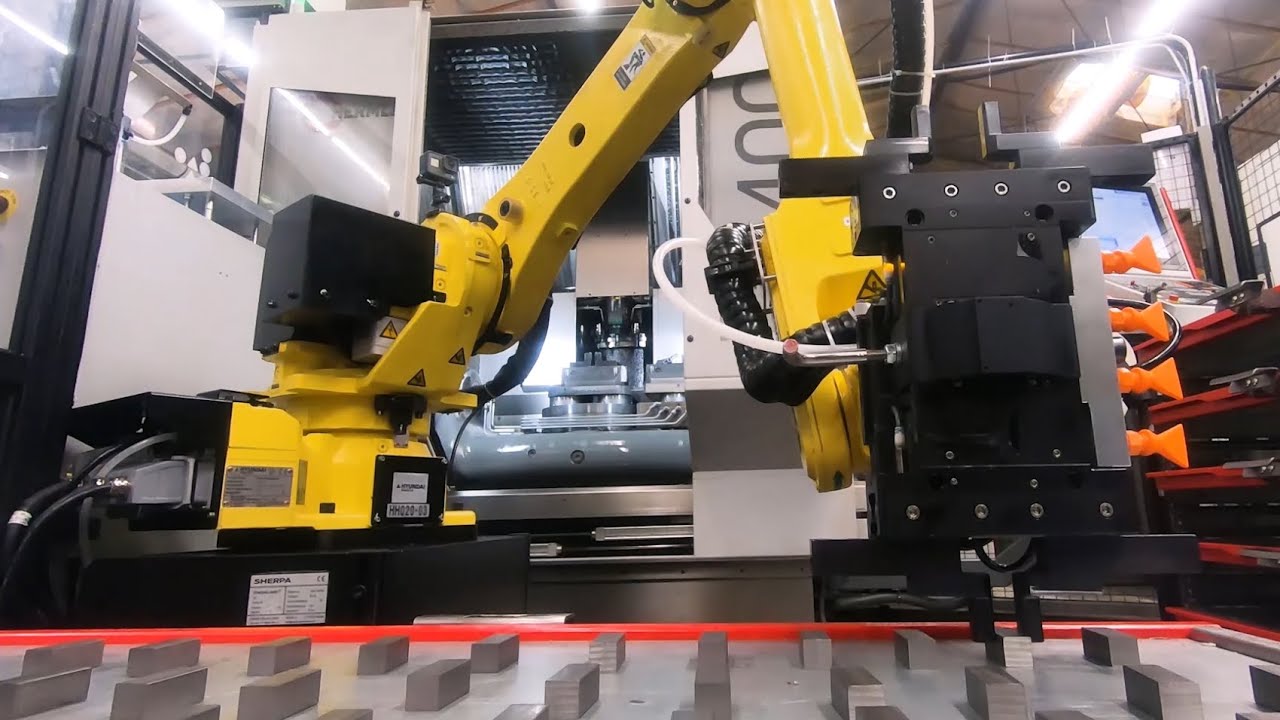

The automation of material provisioning and processing in machining processes with CNC machining machines enables efficient production with maximum machine utilization. This video shows the expansion of the machining process of a Hermle C400 5-axis machining center with a SherpaLoader® M50 with individualized material storage. The diverse possibilities of the SherpaLoader® M50 illustrate how the production process of the Hermle C400 can be efficiently improved.

Material Provisioning with a Flexible Material Storage for the Hermle C400

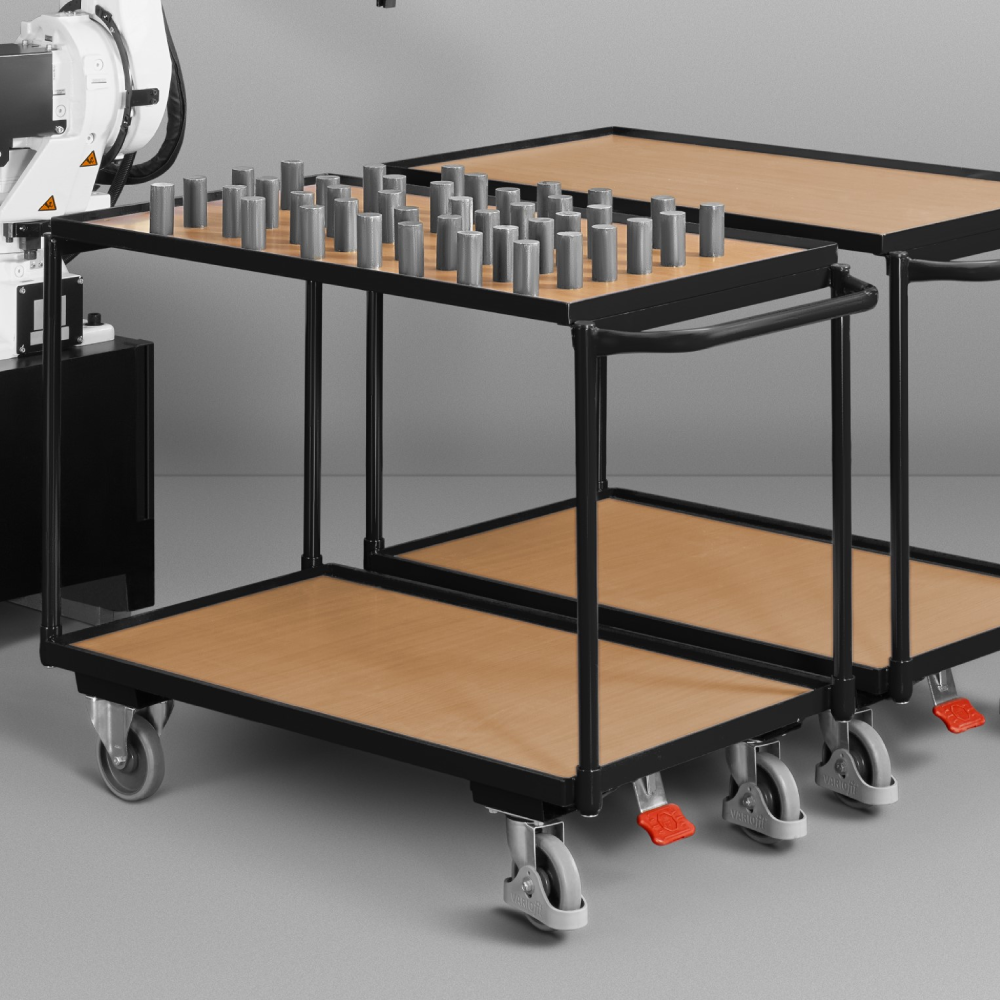

In this process, material provisioning is carried out via SHERPA’s SpaceBox. The SpaceBox can be equipped with up to ten drawers and offers 6 m2 of material storage. The number of drawers can be adapted to the raw part geometries used. In this video, it can be seen that some drawers of the SpaceBox have been removed to enable the provisioning of components with greater height. The material storage for the SherpaLoader® M50 can thus be flexibly adapted to different component geometries. This enables efficient processes, even with changing manufacturing conditions.

Precise Component Positioning Through Intelligent Gripping Technology and Alignment

The gripper of the SherpaLoader® M50 is equipped with a hook with which the drawers of the material storage can be automatically opened. Furthermore, the SherpaLoader® M50 is equipped with a camera. With the advanced detection technology, the SherpaLoader® M50 captures the raw parts on the SpaceBox and can grip them precisely and position them on the alignment plate. The two grippers of the SherpaLoader® M50 are equipped differently to handle raw parts and finished parts differently. The raw part grippers have pendulum jaws with SingerGrip inserts. The pendulum jaws compensate for possible sawing tolerances of the raw parts and thus enable safe transport of the raw parts even under changing conditions. The SinterGrip increases the grip strength and ensures that the raw parts do not slip during transport. On the alignment plate, the raw parts are placed against a defined stop, so that the alignment of the component in the gripper for clamping in the machining machine is ensured. The pre-positioning of the component and the SinterGrip of the raw part gripper enable safe positioning of the component in the Hermle C400 machining center. This ensures high process reliability and consistent component quality.

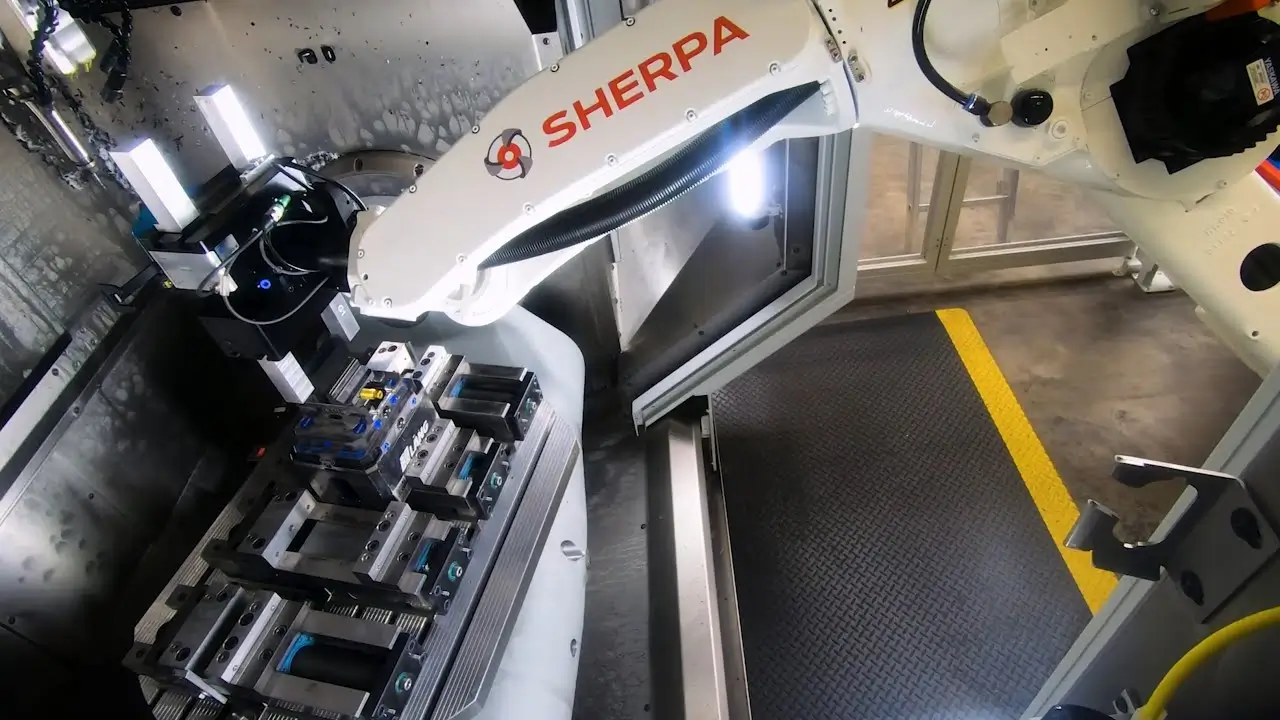

Highest Process Automation on the Hermle C400 Through Torque Screwdriver and Compressed Air Cleaning

Before inserting the raw part into the clamping device of the Hermle C400, the SherpaLoader® M50 cleans the clamping jaws with compressed air. Through automated cleaning, residues from chips or cutting fluids are cleaned off, which increases the repeatability of the clamping process. As another tool, the SherpaLoader® M50 has a torque screwdriver. With the screwdriver, the SherpaLoader® M50 operates the clamping jaws of the Hermle C400 machining center and subsequently leaves the workspace of the system. The reduction of manual interventions through the automation of every process step increases process reliability and enables consistent component quality. Furthermore, personnel management is improved by enabling operators to be deployed for other tasks than machine loading.

Synchronized Processes for Efficiency Improvement of the Hermle C400

While the raw part is being machined in the Hermle C400, the SherpaLoader® M50 already prepares the next raw part and positions it on the alignment plate. After the machining process is completed, the doors of the Hermle C400 open automatically and the SherpaLoader® M50 cleans the finished part with compressed air before loosening the clamping jaws with the torque screwdriver. With the finished part gripper, the SherpaLoader® M50 removes the finished part and cleans the clamping jaws before the next raw part is clamped. Through the preparation of the new raw part during the machining process and carrying the new raw part when removing the finished part, synchronized operations are implemented in the production process. These synchronized processes enable maximum utilization of the Hermle C400 through the reduction of auxiliary times. The finished part is placed back on the material storage and the SherpaLoader® M50 begins preparing the new raw part.

Maximum Productivity and Safety in the Automated Machining Process with the Hermle C400

The complete automation of the production process results in a maximization of spindle time of the Hermle C400 through the introduction of synchronized processes and minimization of auxiliary times. The reduction of manual interventions is achieved through the diverse possibilities of the SherpaLoader® M50. In addition to economic efficiency, the safety of production is also maximized. The machining process has a safety concept that meets the highest safety standards. The robot cell is completely enclosed, the access doors are secured. For access to the manufacturing cell during running automation, a door request must be set. Only when the robot is in a position is the door released and access to the production process is possible. This ensures the safety of personnel.