Efficient Plastic Machining with the Doosan DVF 5000

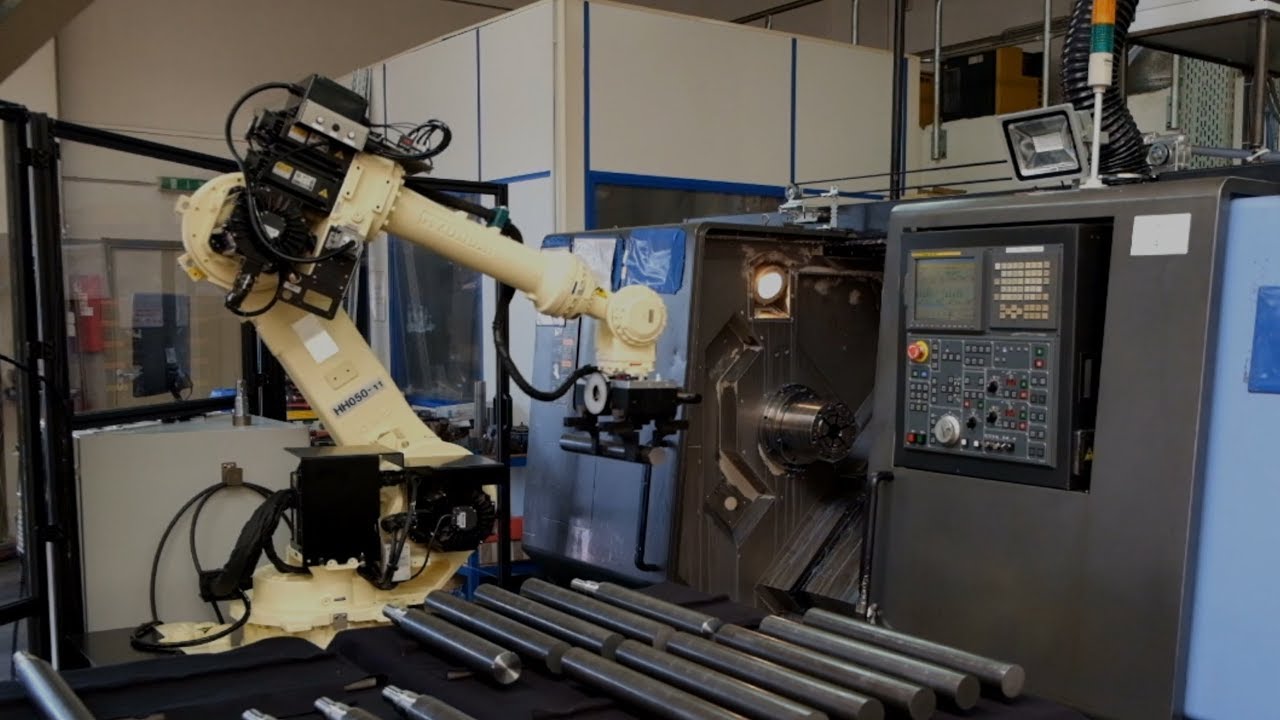

The economical machining of plastic components such as polyoxymethylene (POM) requires adapted handling technology, process-reliable clamping procedures, and efficient component provisioning. This video demonstrates the automation of the machining process for POM components on the 5-axis machining center Doosan DVF 5000 through the integration of a SherpaLoader® M25. The combination of CNC technology, camera-based component detection, and synchronized workflows reduces manual interventions and enables consistent component quality with high machine utilization.

Camera-Assisted Component Detection and Material-Gentle Gripping Technology

The automated material provisioning is carried out via a SpaceBox, whose drawers are opened by the integrated hook of the SherpaLoader® M25. An integrated camera system detects the exact position of the components within the drawer. The detection occurs automatically and enables precise gripping movements independent of tolerances in the storage position. The advanced camera-based detection technology supports flexible process control and increases adaptability to changing component geometries. Through automatic position and orientation detection, different workpiece shapes and positions can be provided without mechanical reconfiguration of the material storage. This reduces setup effort during component changes and enables easy adaptation of the production process to changing manufacturing conditions. The captured raw parts are gripped with the raw part gripper, which – like the finished part gripper – is equipped with pressure-controlled pneumatic grippers. The pressure control ensures that the POM components are held with only as much force as necessary for safe handling. This protects the surfaces and prevents deformation of the workpiece, ensuring high component quality.

Alignment and Automated Cleaning for Process-Reliable Clamping

After removal from the material storage, the raw part is transferred to an alignment plate. There it is positioned against a fixed stop to ensure exact positioning for subsequent clamping. This is followed by automatic cleaning of the clamping device. Before the POM raw part is inserted into the vise of the Doosan DVF 5000, the SherpaLoader® M25 cleans the clamping surfaces with compressed air. This measure prevents clamping errors due to chip residues and increases the repeatability of clamping and component quality. Subsequently, the component is inserted and the machining process begins.

Synchronized Workflows for Maximum Utilization of the Doosan DVF 5000

While the Doosan DVF 5000 performs the machining of the clamped component, the SherpaLoader® M25 already prepares the next component. The SherpaLoader® M25 grips the next raw part from the material storage and positions it on the alignment plate. After completion of the machining, the workspace of the Doosan DVF 5000 opens automatically. The SherpaLoader® M25 removes the finished part from the material clamping and cleans the vise before the new raw part is clamped. Through these synchronized workflows, downtime is reduced and the spindle runtime of the Doosan DVF 5000 machining center is maximized.

Automated Plastic Machining with High Process Stability on the Doosan DVF 5000

The integration of the SherpaLoader® M25 into the machining process of the Doosan DVF 5000 demonstrates how stable and repeatable machining of plastic components can be realized through camera-assisted component detection, controlled gripping forces, automated cleaning, and synchronized movement sequences. Simultaneously, manual interventions are reduced and operating personnel are relieved. The automated solution thus ensures consistent component quality, high machine availability, and an efficient manufacturing process for demanding materials like POM while maintaining the highest safety standards. Personnel safety is ensured through multiple devices. A light curtain with a resolution of 30 mm is integrated on the loading side of the Doosan DVF 5000. The remaining production area is enclosed with a protective device to secure against intervention, crawling under, and reaching over. Additionally, both robot speed and robot position are safely monitored.