Hermle C42 U: Automation as the Key to Productivity Enhancement

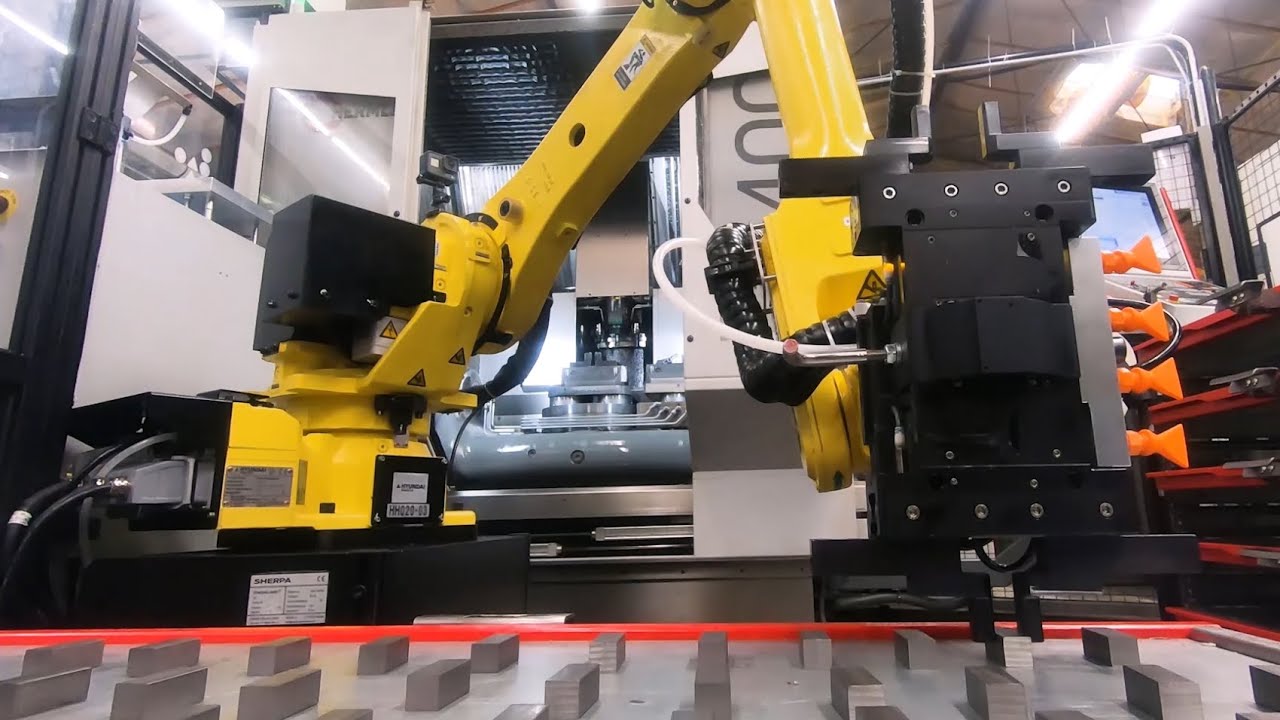

Through the use of automated handling systems, manufacturing processes can be optimized and production capacities better utilized. The integration of the SherpaLoader® M25 into a Hermle C42 U 5-axis machining center with a mechanical vise illustrates how a combination of robotics and modern CNC machines enables high component quality, an optimized machining process, and increased productivity with reduced auxiliary times.

Process Optimization of the Hermle C42 U Through Robotics and Automation

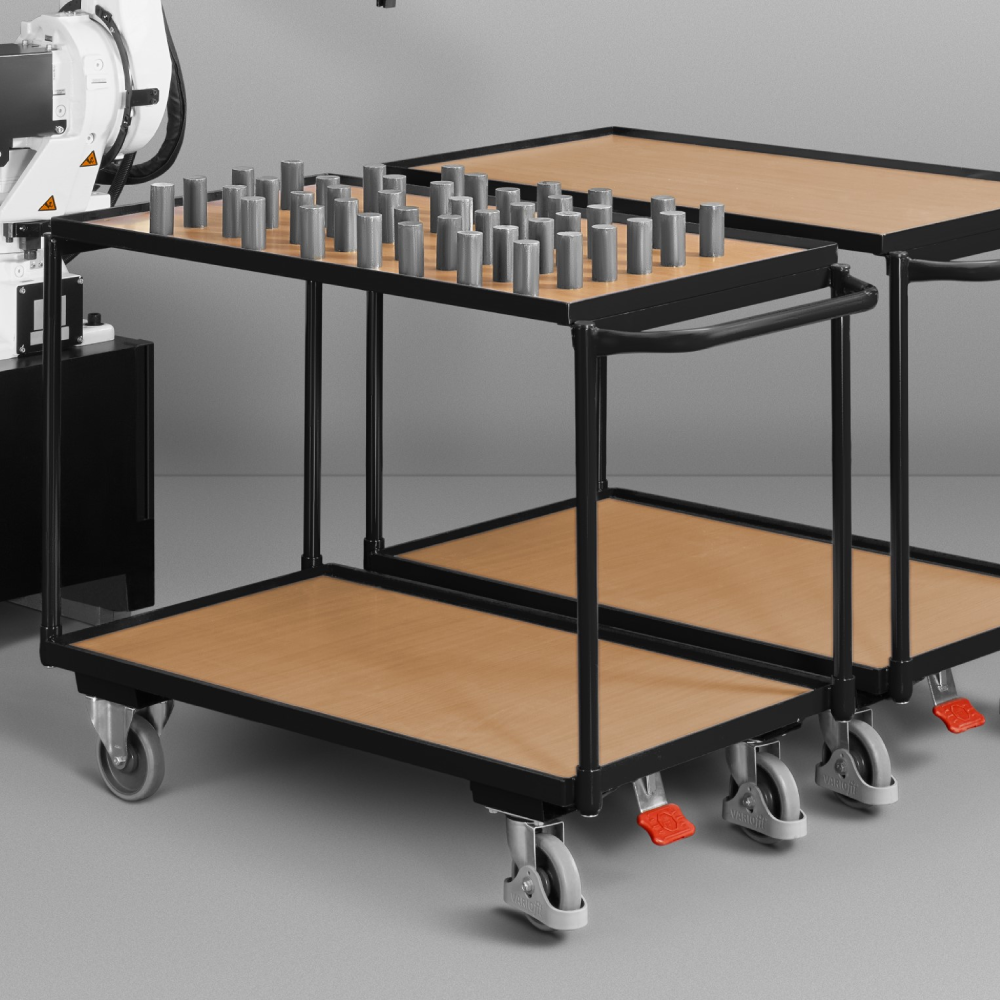

The SherpaLoader® M25 is equipped with multiple tools. The implementation of a hook enables the robot to independently open the drawer for material provisioning. Additionally, the SherpaLoader® M25 features an application-adapted gripping mechanism. The clamping dimension of the electric large-stroke grippers can be set in the system, and the grippers automatically adjust to the required dimension, eliminating the manual effort for gripper adjustment. This automation reduces setup times and enables continuous production without manual interventions. This increases the efficiency of the machining process and optimizes personnel management. The gripping mechanism allows the SherpaLoader® M25 to safely grip the raw parts from the material provisioning and place them on a pre-positioning plate. The capture of components is enabled by the SherpaLoader® M25’s advanced camera-based detection technology. On the pre-positioning plate, the component is placed against a stop. This ensures that the unclamped edge of the component is referenced when it is inserted into the machine’s vise. This achieves increased process reliability and ensures consistent component quality. Once the component is aligned, the SherpaLoader® M25 takes over the insertion of the component into the Hermle C42 U machining center. First, the robot cleans the mechanical vise with compressed air to remove residues such as chips or cutting fluid. This minimizes potential sources of error and enables precise manufacturing. Subsequently, the SherpaLoader® M25 positions the component in the vise. With the integrated torque screwdriver, the SherpaLoader® M25 independently clamps the vise. The doors of the machining center close automatically.

Synchronized Process Sequences: Maximum Productivity of the Hermle C42 U

Parallel to the main time of component machining, the SherpaLoader® M25 positions a new raw part on the pre-positioning plate. The synchronization of processes through the integration of the SherpaLoader® M25 results in a reduction of auxiliary times and maximization of the spindle runtime of the Hermle C42 U. Once the machining process is completed, the doors of the Hermle C42 U machining center open. The robot releases the vise, removes the machined component, and performs renewed cleaning of the vise. This extends the machine’s lifespan and reduces maintenance effort. An optimization of production time is achieved by the SherpaLoader® M25 already carrying the new raw part when removing the machined workpiece and inserting it directly into the machining center’s vise after cleaning. The machined component is placed back on the material provisioning and the SherpaLoader® M25 grips a new raw part.

Flexible Machining Through Camera-Based Detection Technology

With the integrated camera-based detection technology, the SherpaLoader® M25 precisely captures the position of components and reliably positions them in the Hermle C42 U machining center using the electric large-stroke gripper. The advanced image processing technology enables exact and rapid identification of different component geometries. This allows the machining process to be flexibly adapted to various workpiece shapes. The ability to dynamically adapt gripping and positioning strategies minimizes setup times and reduces the need for manual changeover procedures. Furthermore, the automated process adaptation results in higher machine utilization and increased process stability. This optimizes production cycles and significantly reduces production costs.

Efficient Automation Solution for the Hermle C42 U Machining Center

The SherpaLoader® M25 represents an efficient automation solution for use in machining centers. Through flexible adaptation to different customer requirements and technical conditions, it contributes to increasing productivity and reducing manual interventions. The automation enables minimization of setup times, high process stability, and increased machine runtime. This leads to maximum process productivity while maintaining high component quality. Additionally, the SherpaLoader® M25 ensures the highest safety standards and stable process reliability.