Efficient Machining of Coated Metal Housings with the SherpaLoader® M25

The automated machining of coated metal housings places high demands on handling, process reliability, and component protection. This video demonstrates the automation of machining on a HAAS VF-3SS 5-axis machining center through the integration of a SherpaLoader® M25. The combination of a powerful machining center and intelligent handling robot enables economical manufacturing with consistently high component quality and efficient personnel deployment.

Gentle Handling Thanks to Plastic Inserts

The SherpaLoader® M25 is equipped with two grippers – a raw part and a finished part gripper – as well as with a torque screwdriver and a hook for operating the material provisioning. The gripper fingers are designed as width spans with TPE hard rubber inserts that protect the coated surfaces of the metal housings. The rubber dampens peak loads, prevents damage, and simultaneously ensures secure fixation of the workpieces. This enables gentle, component-appropriate automation even for sensitive components.

Precise Alignment and Automatic Clamping Technology for High Repeatability

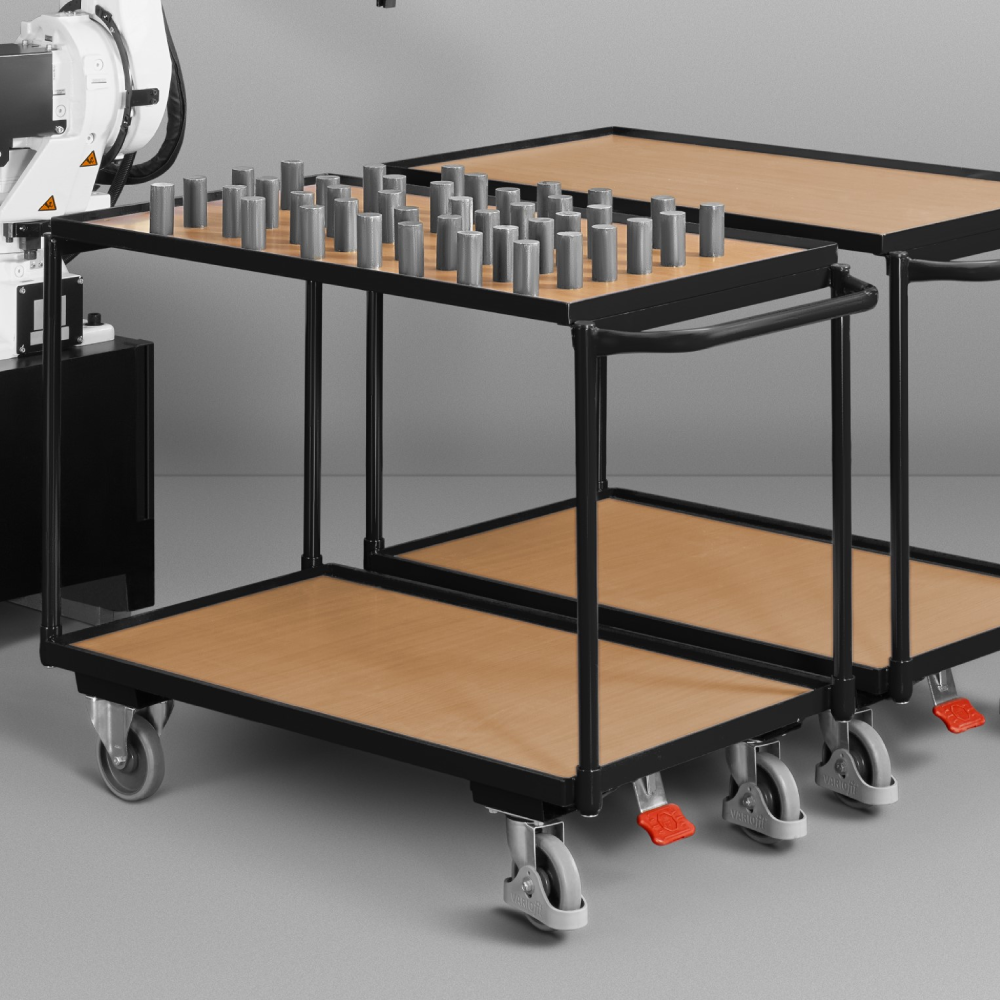

The raw parts are provided in SHERPA’s SpaceBox. With the integrated hook, the SherpaLoader® M25 automatically opens the first drawer of the SpaceBox and removes the first raw part. The position of the SpaceBox is previously automatically detected by an integrated laser, so that access to the drawers can be precise and repeatable. Subsequently, the SherpaLoader® M25 positions the part on the alignment plate, where it is placed against a fixed stop. This ensures exact positioning for subsequent clamping. After alignment, the component is gripped again and transferred into the workspace of the HAAS VF-3SS. Before the workpiece is clamped in the vise, the SherpaLoader® M25 automatically cleans the clamping jaws with compressed air to remove chips and cutting fluids. This measure increases the repeatability of clamping, protects the surface of the component, and reduces wear on the clamping device. Subsequently, clamping is performed by the integrated torque screwdriver, which automatically operates the vise with defined torque. By reducing manual interventions, process reliability increases while simultaneously ensuring consistently high component quality and optimized personnel deployment planning.

Synchronized Workflows for Maximum Spindle Utilization of the HAAS VF-3SS

As soon as the machining process starts, the SherpaLoader® M25 already begins preparing the next raw part. It removes the component from the material storage, aligns it on the alignment plate, and keeps it ready for the next machining step. These synchronized processes minimize auxiliary times and ensure maximum spindle runtime. After completion of machining, the doors of the HAAS VF-3SS open automatically. The SherpaLoader® M25 opens the vise with the torque screwdriver, removes the finished part with the finished part gripper, and cleans the vise again with compressed air to keep the conditions for subsequent clamping stable and process-reliable. After automated cleaning, the new raw part is positioned in the vise and the vise is clamped. As soon as the SherpaLoader® M25 leaves the HAAS VF-3SS machining center, the doors close and the machining process begins again. The finished part is placed on the material storage.

Maximum Efficiency: Machining Automation of the HAAS VF-3SS

The complete integration of the SherpaLoader® M25 into the machining process of the HAAS VF-3SS demonstrates how reduced manual interventions, automated cleaning processes, gentle gripper technology, and synchronized workflows lead to maximum machine availability and consistently high component quality. Simultaneously, personnel are relieved from simple handling tasks and can be deployed for value-adding activities. The automated solution thus convinces through productivity, process reliability, and economic efficiency – even with sensitive workpieces and varying requirements. The highest safety requirements are always met. The loading side of the robot cell is safely monitored via a light curtain with a resolution of 30 mm. The remaining production area is secured via a protective device to safeguard against intervention, crawling under, and reaching over. During production, both robot position and robot speed are also safely monitored.