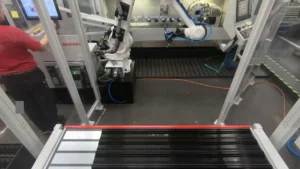

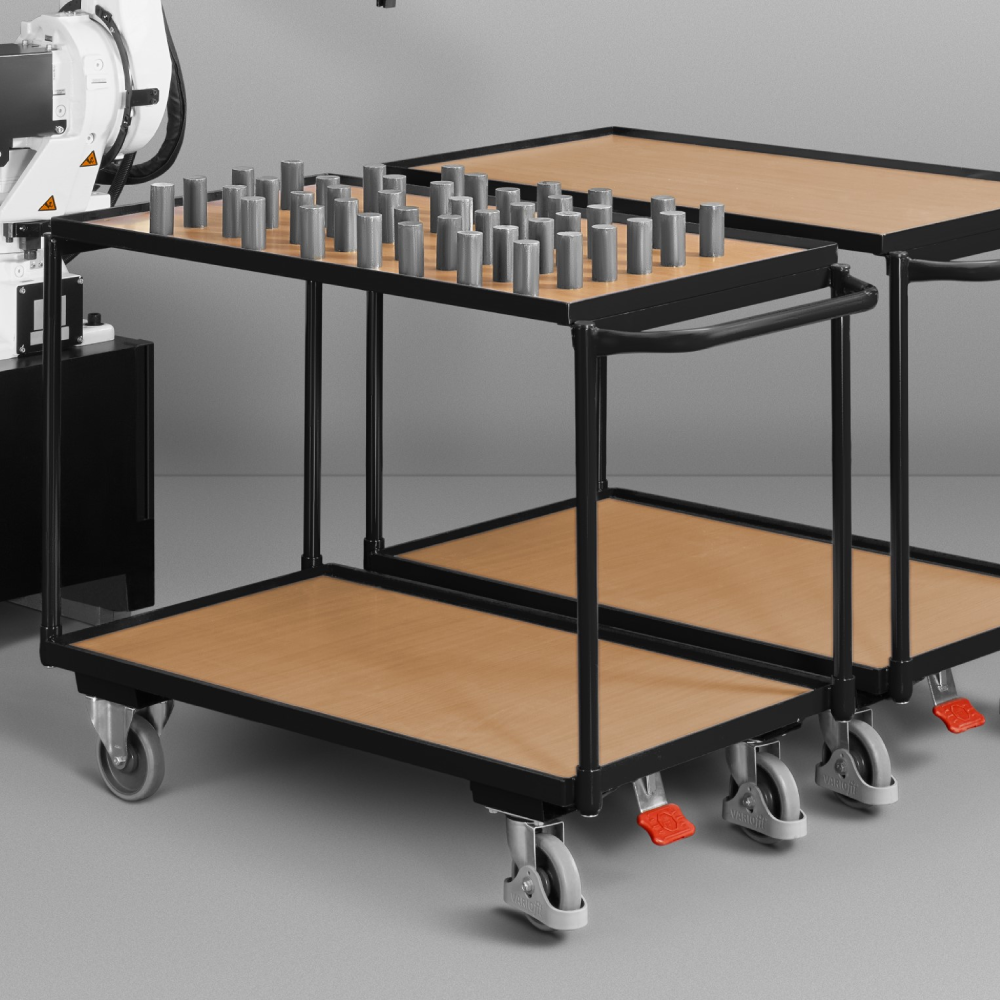

Automation of a Spinner 4-axis CNC machine

When implementing automation solutions in the manufacturing process, specific requirements must be taken into account in order to increase productivity. The integration of the SherpaLoader® into this process illustrates how coordinated technologies can meet these requirements and optimize the production process.