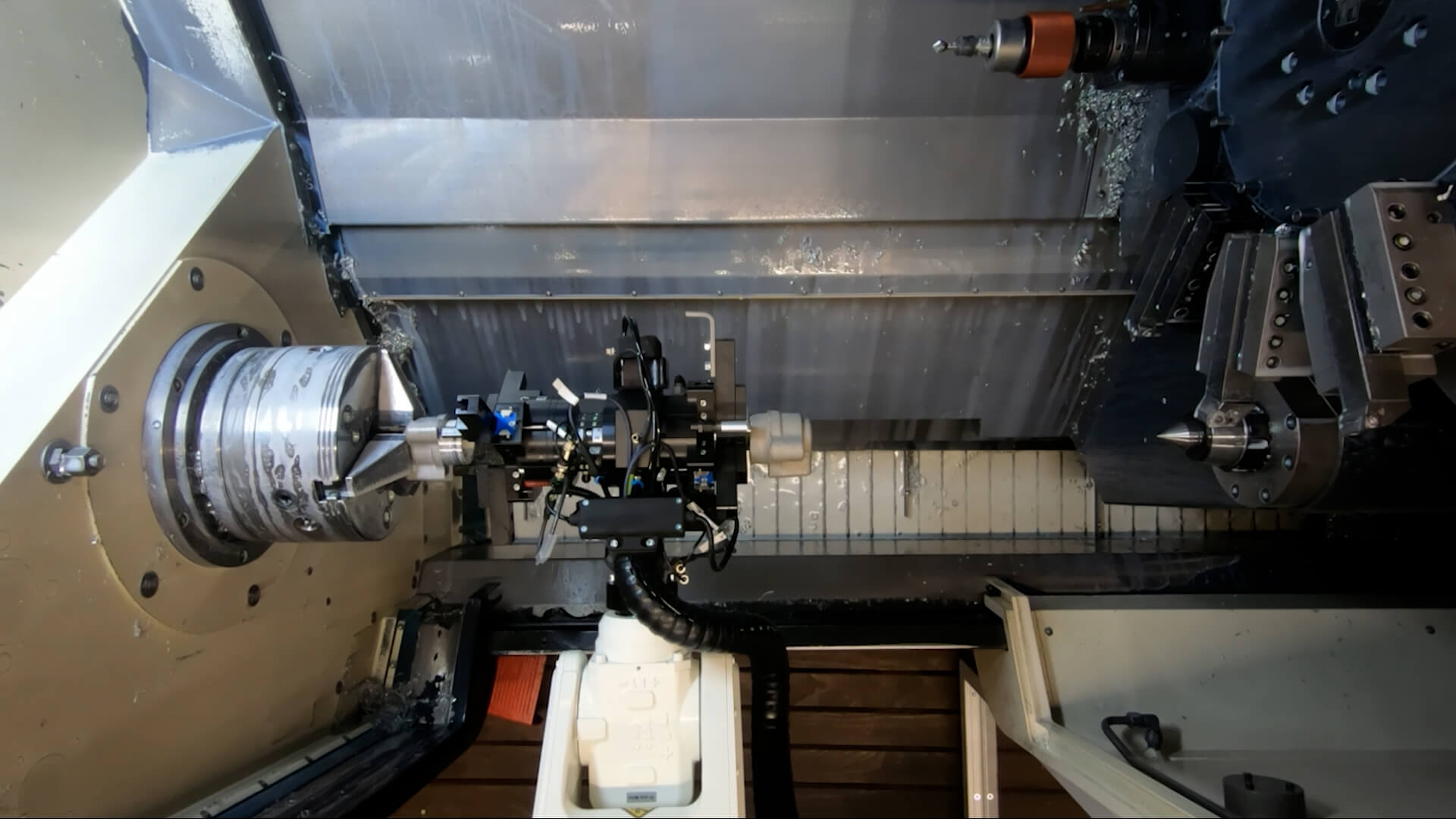

Not only for the DMU, our automation solution enables flexible loading via the working or side door, while maintaining access to existing tool magazines and chip conveyors. With additional options for the spindle, tool magazine, and measuring technology, the automation ensures precise control processes – whether stackable or non-stackable workpieces are involved. The seamless integration of the swivel arm into the control system as well as full compatibility with DMG Profibus complete the performance package.

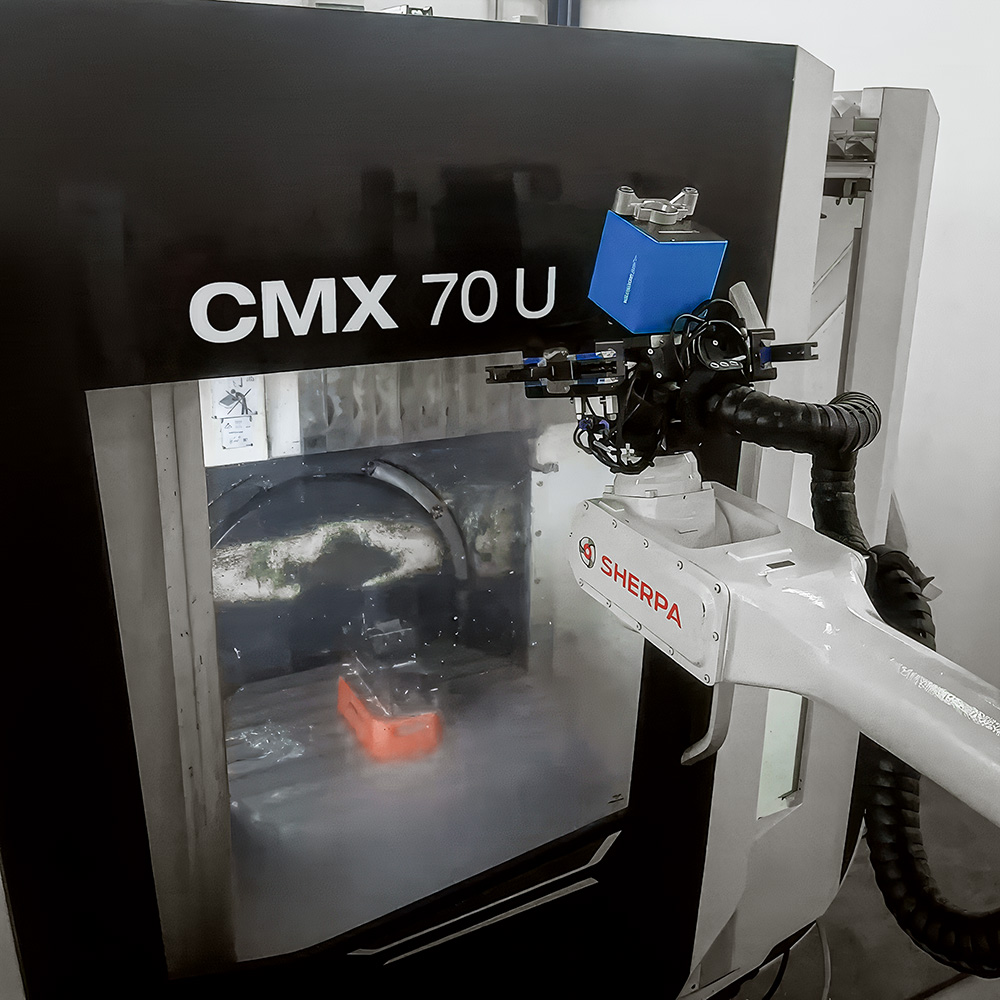

Our approach also benefits the CMX. The automation solution allows flexible loading via working or side doors, while unrestricted access to existing tool magazines and chip conveyors is maintained. Thanks to the available options for the spindle, tool magazine, and measuring technology, both stackable and non-stackable workpieces are processed efficiently. In addition, the optimal integration of the swivel arm together with full DMG Profibus compatibility ensures smooth production processes.

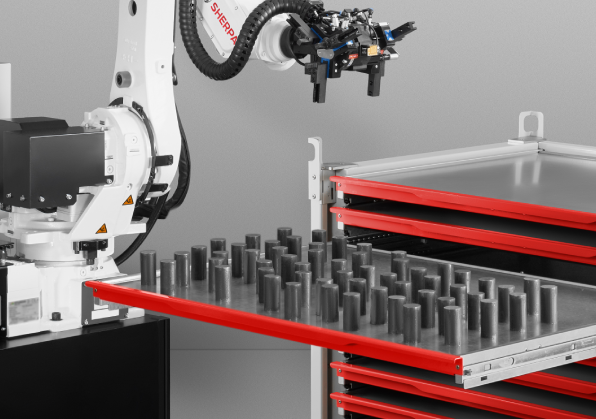

For the DMV series, the focus is on flexible material feeding, which ensures optimal supply for both small and large workpieces. This concept is complemented by the option of a turning station for backside machining and the possibility of using multiple clamping setups on the large table – ideal for processing a wide variety of workpiece types, whether stackable or not.