Efficiency Through Machining Automation

The automation of machining processes with CNC machining machines offers great potential to improve production efficiency while achieving high component quality. This video shows the expansion of the machining process of small round material on a Mazak QT200 MSY with a SherpaLoader® T25. The automation of process steps starting from material provisioning, through clamping of raw parts in the Mazak QT200 MSY to post-processing of finished parts enables high process stability through the reduction of manual interventions. The implementation of synchronized processes reduces auxiliary times and enables maximum machine utilization as well as maximum process productivity.

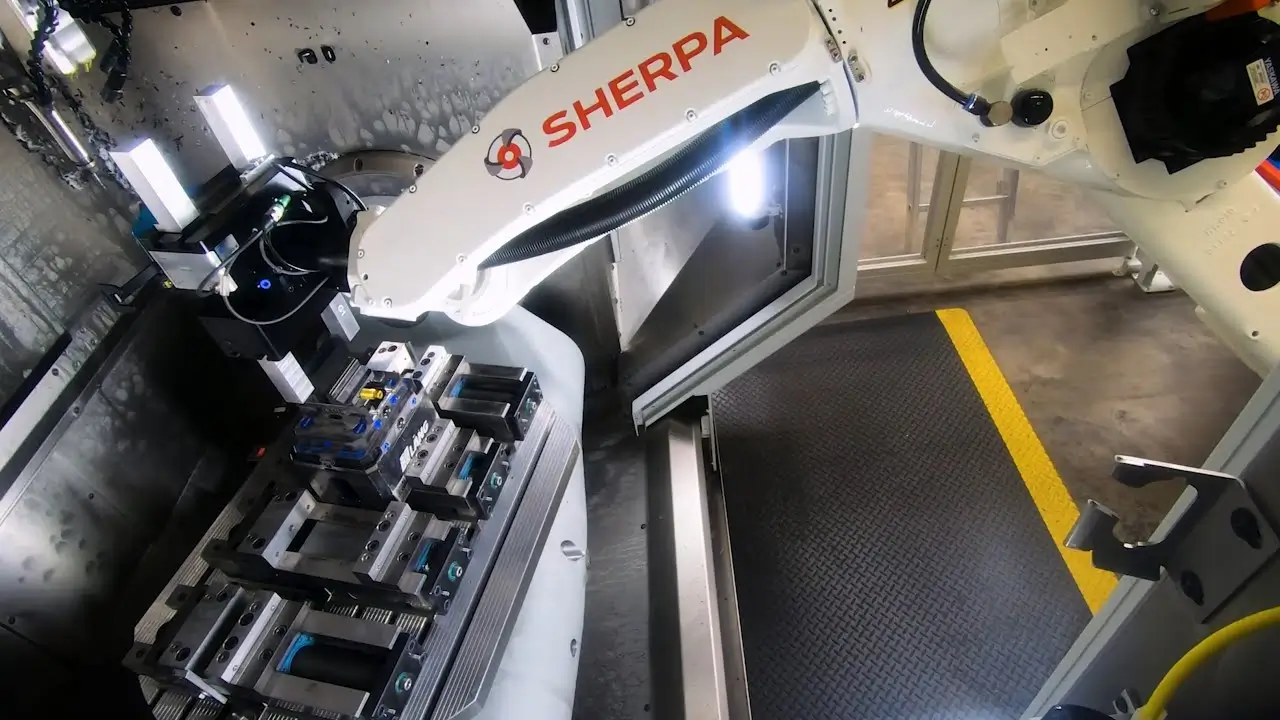

Maximum Automation of the Mazak QT200 MSY Through Flexible Robot Equipment

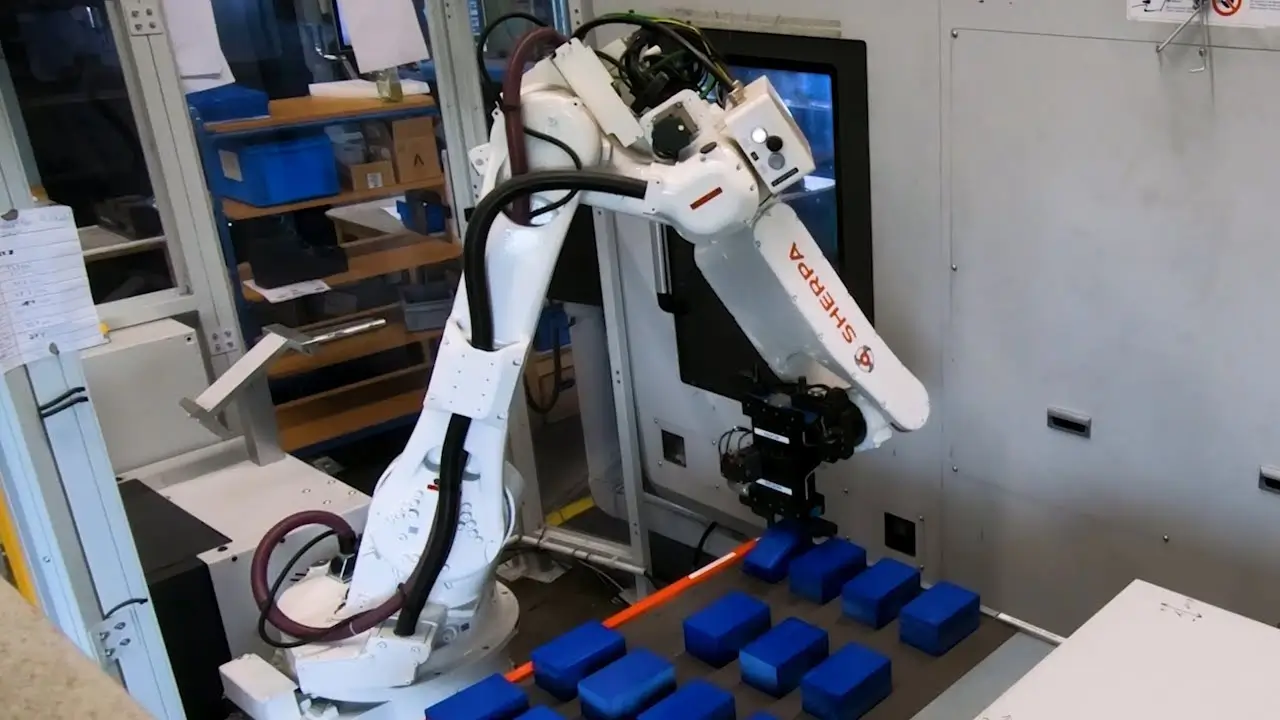

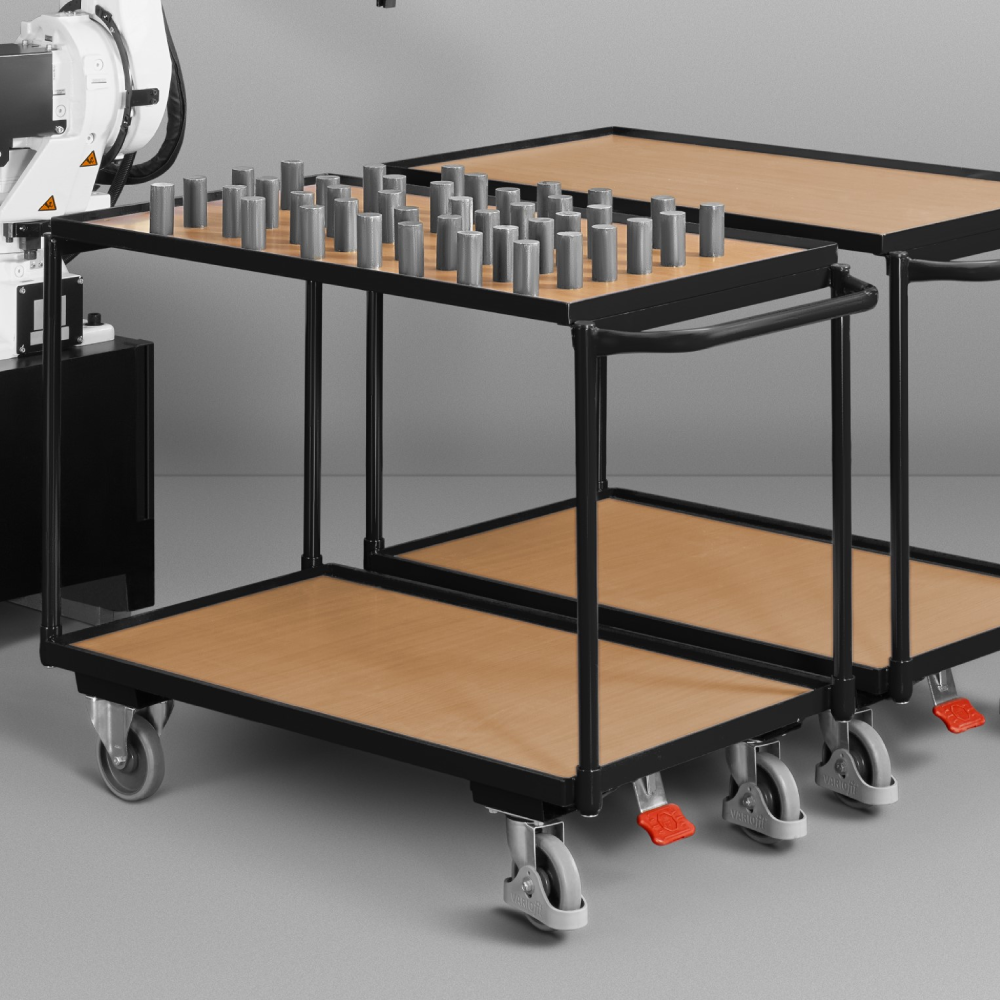

The material provisioning of the process is carried out via a SpaceBox with ten drawers. Equipped with an operating hook, the SherpaLoader® T25 opens the first drawer of the material storage. The position of the material storage is determined via a laser integrated on the robot. This enables flexible positioning of the material storage. The arrangement of the raw material is captured via the advanced camera-based detection technology with which the SherpaLoader® T25 is equipped. Furthermore, the robot is equipped with two three-jaw grippers. The equipment of the SherpaLoader® T25 with different tools enables simple and versatile adaptation of the production process to changing workpiece geometries and process sequences.

Maximum Machine Utilization of the Mazak QT200 MSY Through Synchronized Process Control

With one of the two three-jaw grippers, the SherpaLoader® T25 precisely grips the raw parts and places them on the alignment plate. The aligned raw part is then clamped into the main spindle of the Mazak QT200 MSY. The automated alignment of the raw parts increases process reliability and ensures consistent component quality. After the SherpaLoader® T25 has left the machining area of the Mazak QT200 MSY, the door closes automatically and the machining process begins. During machining, the SherpaLoader® T25 already prepares the next raw part to clamp it into the Mazak QT200 MSY after positioning on the alignment plate. Through the integration of synchronized processes, a steady material flow is enabled. This minimizes auxiliary times and maximizes the spindle time of the Mazak QT200 MSY. As soon as the machining process is completed, the door of the Mazak QT200 MSY opens automatically. During machining of the workpieces, they are transferred from the main spindle to the sub-spindle, and the SherpaLoader® T25 removes the finished part from the sub-spindle.

Stable Machining Processes Through Automated Cleaning

The SherpaLoader® T25 cleans the finished part with compressed air before removing it from the sub-spindle with its second three-jaw gripper. Likewise, the main spindle of the machining machine is cleaned with compressed air before the next raw part is inserted. The automated cleaning of the main spindle of the Mazak QT200 MSY ensures that no residues from chips or cutting fluid are present. This ensures process reliability and repeatability of the clamping system as well as dimensional accuracy of the components. Furthermore, wear of machine parts is reduced when this is caused by contamination. This leads to longer maintenance intervals and promotes production efficiency. During removal of the finished part from the sub-spindle, the robot already carries the next raw part to clamp it into the main spindle of the Mazak QT200 MSY. The finished part is placed back on the material storage and the SherpaLoader® T25 prepares the next raw part.

Process Automation of a Mazak QT200 MSY with the Highest Safety Standards

The process automation of the Mazak QT200 MSY through integration of the SherpaLoader® T25 enables optimization of machine utilization and process reliability by reducing manual interventions and auxiliary times through synchronized process steps. The highest safety standards are always met. To ensure safety during the production process of the Mazak QT200 MSY, the production system is equipped with a light barrier that monitors all accessible areas of the production space.