Production Optimization Through Automation of the DMG Mori DMU 60eVo with SherpaLoader® M25

The automation of machining processes minimizes the number of manual interventions and increases process reliability as well as component quality. This video demonstrates how the production process of a DMG Mori DMU 60eVo 5-axis machining center is enhanced through automation with a SherpaLoader® M25.

Automated Machining with Material Storage and the DMG Mori DMU 60eVo

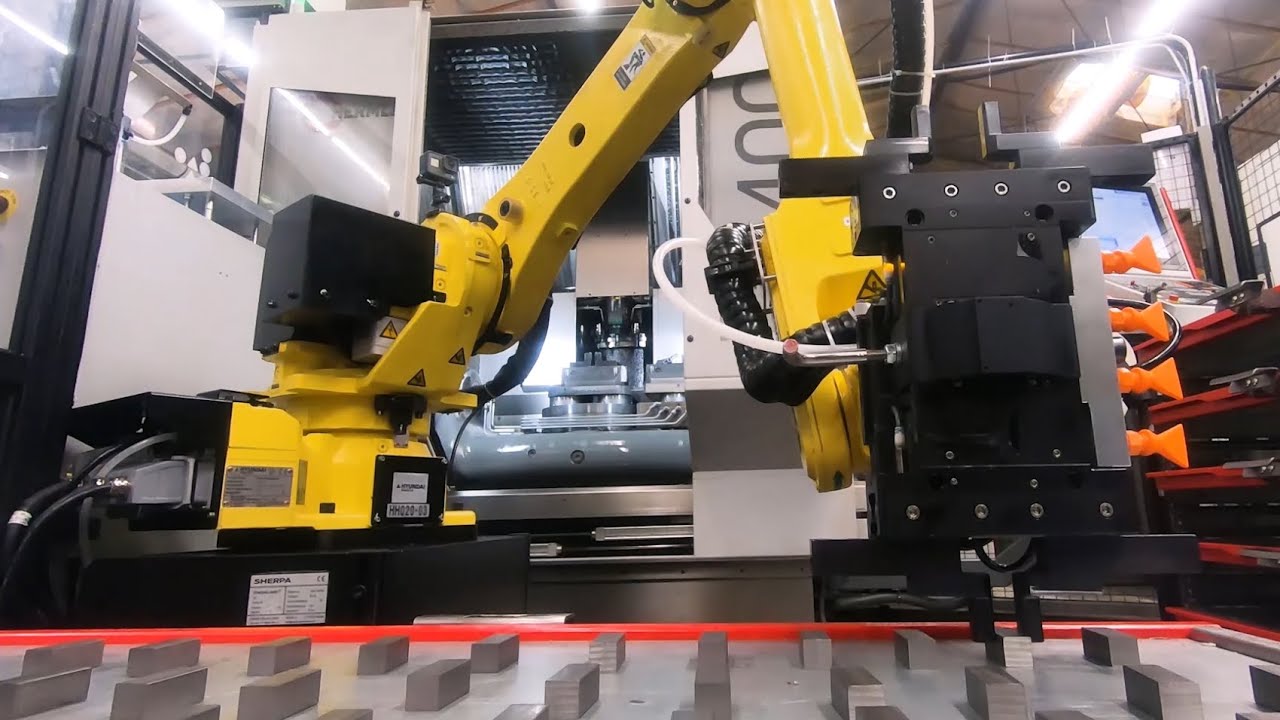

The production process consists of a DMG Mori DMU 60eVo 5-axis machining center with round door, a SherpaLoader® M25, and a material storage system. Furthermore, the production is equipped with a comprehensive safety concept that meets the highest standards. The work area is secured by a light curtain and a sliding door. The material provisioning is carried out via a SpaceBox, in which raw parts are arranged in a matrix plate. This minimizes position deviations in the material storage and enables the loading robot to remove the raw parts according to the matrix. This ensures a constant material flow and maximum machine utilization of the DMG Mori DMU 60eVo. The SherpaLoader® M25 is equipped with a hook with which it automatically operates the drawers of the SpaceBox. After pulling out a drawer, the robot grips the first raw part and places it on the alignment plate before clamping in the machining machine. This creates high customer satisfaction.

Optimized Clamping in the DMG Mori DMU 60eVo Through Cleaning and Torque Screwdriver

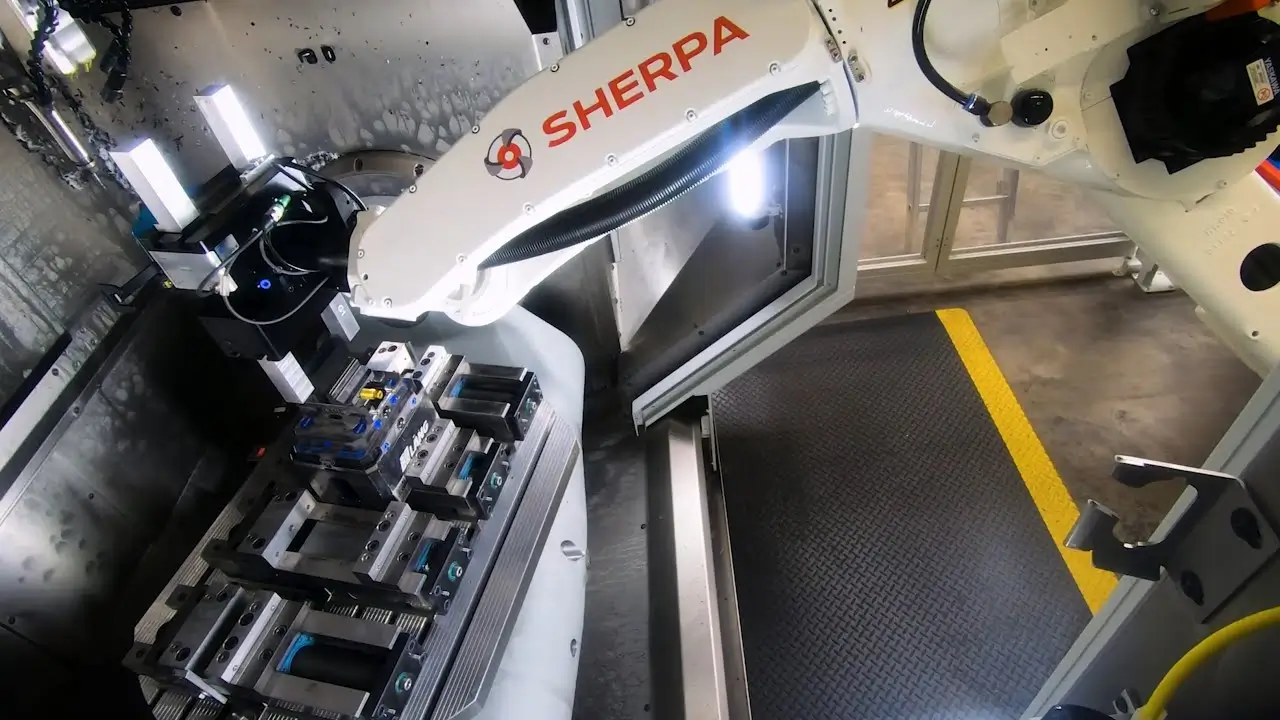

After alignment, the robot arm positions the raw part in the DMG Mori DMU 60eVo machining center. The loading robot was mounted on a base with an inclination of 30° to increase accessibility in the DMG Mori DMU 60eVo. The diverse integration possibilities of the SherpaLoader® M25 in machining processes allow flexible automation of different productions. Before the raw part is clamped in the vise of the DMG Mori DMU 60eVo, the robot arm cleans the clamping jaws of the vise with compressed air to remove residues from chips and cutting fluid. Through automated cleaning, the repeatability of clamping and thus the component quality are increased. Additionally, wear of the system due to contamination and thus maintenance effort are reduced. The clamping of the raw part in the vise is also performed automatically. For this purpose, the gripper arm is equipped with a torque screwdriver from Allmatic. With the Robobuddy, the robot can clamp the raw part with a defined torque in the vise. The automation of individual process steps reduces manual interventions and increases process reliability. This ensures consistent component quality. Additionally, personnel can be deployed for other activities.

Synchronized Process Steps for Maximizing Spindle Time of the DMG Mori DMU 60eVo

After the gripper arm has left the workspace of the DMG Mori DMU 60eVo, the round door closes automatically and the machining process begins. The round door was also retrofitted with a drive by SHERPA Robotics. This allows process adjustments to be made with minimal effort. While the component is being machined in the DMG Mori DMU 60eVo, the loading robot already prepares the next raw part on the alignment plate. Through the implementation of synchronized processes, auxiliary times are reduced and the utilization of the DMG Mori DMU 60eVo is maximized. This leads to increased economic efficiency of production. After the machining process is completed, the automation arm cleans the finished part with compressed air and releases the vise of the DMG Mori DMU 60eVo machining center. Subsequently, the finished part is removed and the clamping jaws of the vise are cleaned again with compressed air. Since the SherpaLoader® M25 already carries the new raw part, it can be inserted into the DMG Mori DMU 60eVo immediately after cleaning and clamped. The next finished part is placed back on the material storage.