Optimization of Manufacturing Processes Through Automation

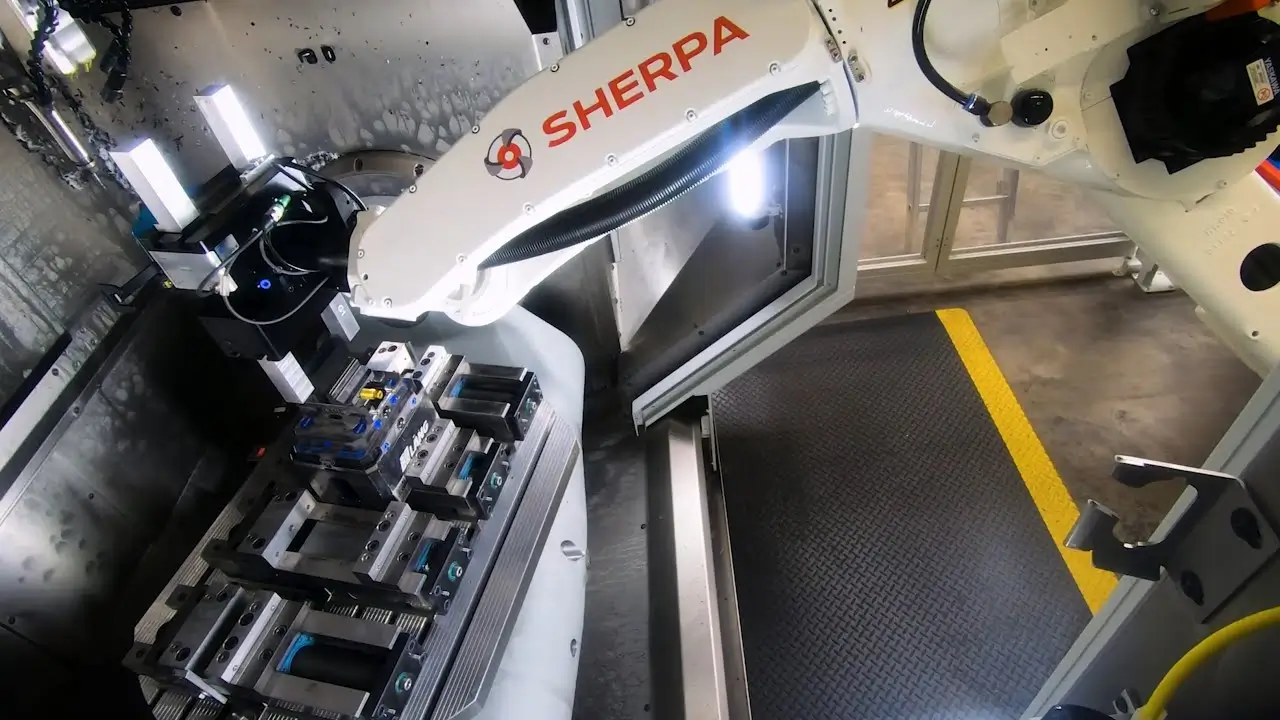

This video demonstrates how the integration of the SherpaLoader® T88 into a manufacturing process with an AXA HFB1 Duo machining machine optimizes the production process and enables automated machining of shafts. Through automated material handling, the manufacturing process is made more efficient and manual interventions are reduced, thereby lowering production costs, increasing process stability, and minimizing error rates. This leads to higher machine utilization and improved manufacturing efficiency.

The Automated Machining Process for the AXA HFB1 Duo

The SherpaLoader® T88 removes the raw parts with a shaft gripper from a prism support and places them on the alignment station. At the alignment station, the component is referenced against a fixed stop. Through referencing, consistent component positioning in the AXA HFB1 Duo and thus precise and controlled further processing is ensured. After referencing, the raw part is transferred into the machine’s workspace. After automatic closing of the machine doors, the workpiece is fixed by hydraulic clamping devices before the machining process begins.

Automated Cleaning: Ensuring Highest Quality

After completion of the machining process, the machine protection doors of the AXA HFB1 Duo open automatically and the SherpaLoader® T88 removes the finished component. To remove chips and cutting fluid specifically from the cut threads at the component ends, the workpiece is guided to a cleaning blow box. Here the end faces are specifically cleaned. Finally, the cleaned finished part is placed back on the material provisioning before the SherpaLoader® T88 picks up the next raw part for machining. The automated cleaning of components after the machining process ensures that cut thread turns remain free from contamination and all raw parts are manufactured with the same quality. Additionally, automated cleaning enables both direct further processing when integrating additional process steps as well as longer storage of components. This allows the robot to work autonomously for longer periods without the components requiring post-processing due to adhering chips, and manufacturing waste is thus avoided. This further increases process efficiency by reducing auxiliary times.

Adaptation of the SherpaLoader® to Different Component Geometries

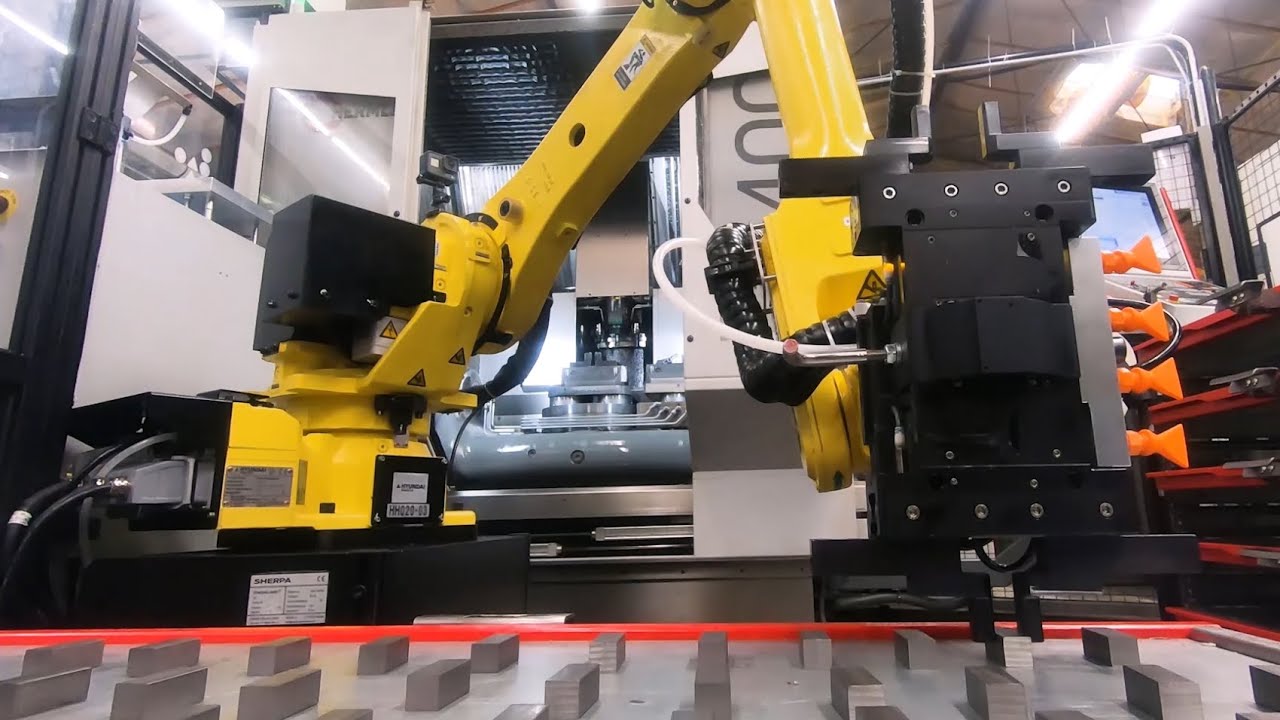

The SherpaLoader® T88 enables simple adaptation to different workpiece geometries. When using camera-based detection technologies, various component geometries can be automatically captured and the automation process adapted accordingly. This allows the SherpaLoader® T88 to be combined with different machining centers and the production process to be flexibly adapted to changing manufacturing conditions.

Process Optimization of the AXA HFB1 Duo Through Machining Automation

The SherpaLoader® T88 optimizes the machining processes of the AXA HFB1 Duo through reliable and automated material handling. Its flexibility enables adaptation to different workpiece requirements and can thus be integrated into various processes. Auxiliary times are reduced and process reliability is increased, while always meeting the highest safety standards. Through reduced manual effort, the SherpaLoader® T88 contributes to efficient and stable manufacturing and supports companies in optimally utilizing their production capacities.